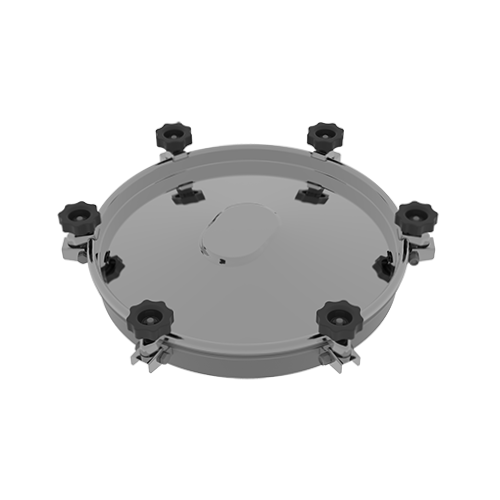

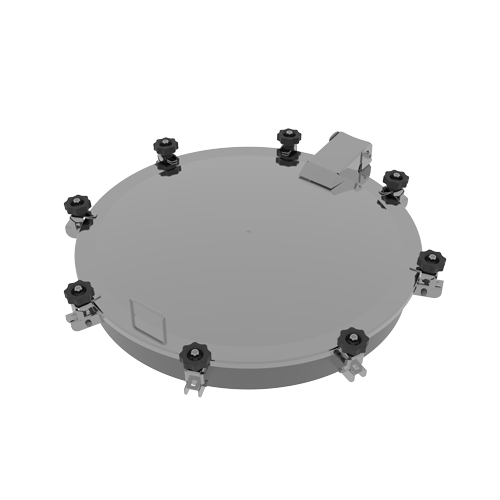

Round manway

W1/C/MINI (DN150)

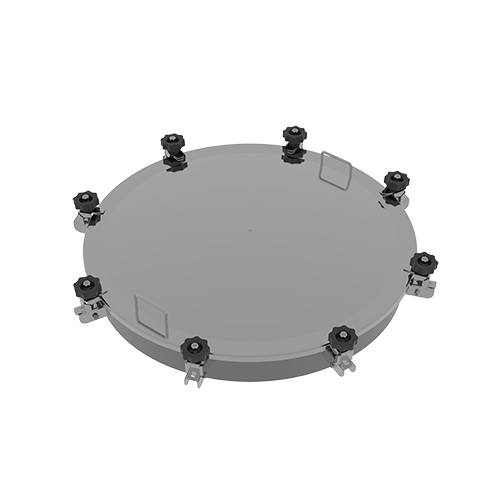

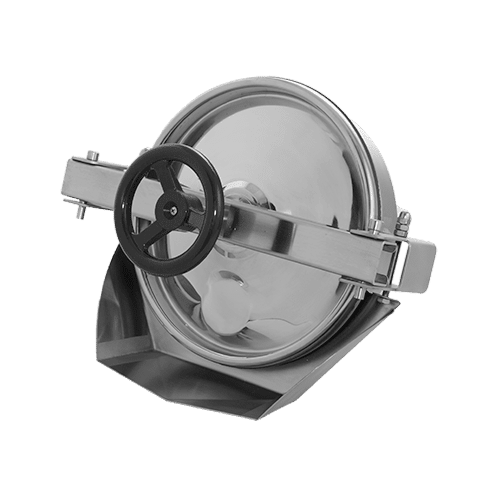

Round manway

W1/A (DN220-DN600)

Rectangular manway

W2/D (424x316)

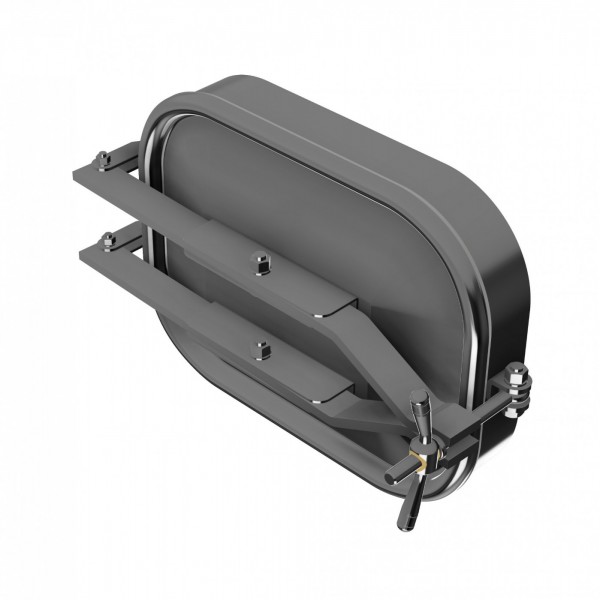

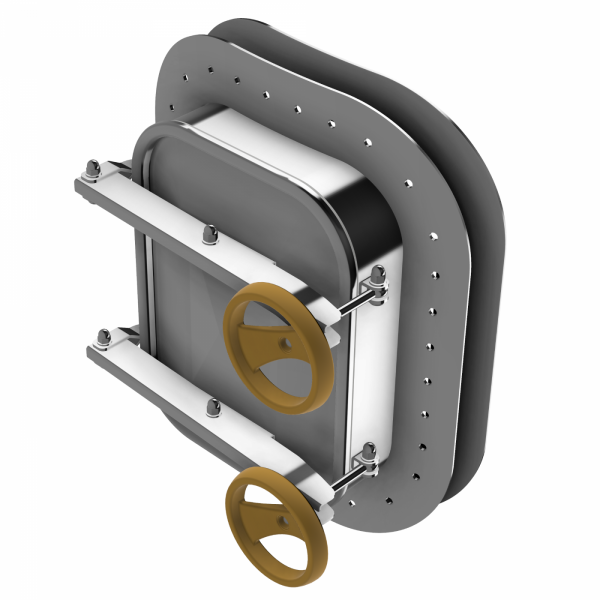

Oval manway

W3/F (440x308)

Special-purpose manway

W2/A/PE (530x406)

Rectangular manway

W2/E (175x225)

Rectangular manway

W2/A (530x406)

Rectangular manway

W2/F (245x310)

Round manway

W4/A (DN220-DN500)

Round manway

W4/B (DN220-DN500)

Round manway

W4/C (DN220-DN500)

Round manway

W4/D (DN220-DN500)

Rectangular manway

E115 (530x406)

Rectangular manway

E116 (406x530)

Round manway

E117 (DN300)

Round manway

E118 (DN400)

Rectangular manway

E121 (424x316)

Rectangular manway

E122 (316x424)

Rectangular manway

E123 (424x316)

Rectangular manway

E124 (316x424)

Oval manway

E125XL (550x450)

Oval manway

E126 (340x450)

Oval manway

E126/1 (440x340)

Oval manway

E126RS (440x340)

Oval manway

E128RS (440x308)

Oval manway

E127 (440x308)

Oval manway

E127/1 (444x312)

Oval manway

E128T (440x308)

Oval manway

E128TS (440x308)

Rectangular manway

E129 (530x406)

Rectangular manway

E130 (424x316)

Rectangular manway

E131 (424x316)

Rectangular manway

E132 (450x750)

Rectangular manway

E133 (600x800)

Oval manway

E156 (540x410)

Oval manway

E157 (440x308)

Oval manway

E158 (440x308)

Rectangular manway

E134 (600x800)

Rectangular manway

E135 (800x1000)

Round manway

E15P (DN150)

Round manway

A550 (DN300-DN600)

Round manway

A560 (DN200-DN600)

Round manway

A560R (DN300-DN600)

Round manway

A570 (DN200-DN600)

Round manway

A570R (DN300-DN600)

Round manway

A580 (DN200-DN600)

Round manway

A590 (DN300-DN600)

Round manway

A540 (DN200-DN600)

Round manway

A520 (DN200-DN600)

Round manway

A930 (DN150-DN600)

Round manway

E/S (DN223-DN602)

Round manway

A940 (DN220-DN600)

Round manway

A960 (DN150-DN600)

Round manway

A960R (DN220-DN600)

Round manway

A970 (DN150-DN600)

Round manway

A970R (DN220-DN600)

Round manway

A980 (DN220-DN600)

Round manway

E/1S (DN223-DN602)

Round manway

A1020 (DN300-DN600)

Round manway

E/P (DN223-DN602)

Round manway

A1080 (DN800-DN1200)

Round manway

A1090 (DN800-DN1200)

Round manway

A790 (DN200-DN300)

Round manway

A800 (DN300-DN420)

Round manway

A800R (DN380-DN420)

Round manway

E/1P (DN223-DN602)

Oval manway

A304 (305x430)

Round manway

E/M (DN223-DN602)

Oval manway

A306 (305x430)

Oval manway

A307 (305x430)

Oval manway

A308 (345x445)

Round manway

E/1M (DN223-DN1540)

Round manway

E/1D (DN402-DN602)

Oval manway

A309 (345x445)

Round manway

E/1B (DN502-DN792)

Oval manway

A309IG (345x445)

Oval manway

A310 (400x490)

Oval manway

A311 (305x430)

Oval manway

A311G (305x430)

Oval manway

A312 (305x430)

Oval manway

A314 (400x490)

Oval manway

A315 (400x490)

Oval manway

A316 (345x445)

Oval manway

A317 (345x445)

Oval manway

A317E (345x445)

Oval manway

A318 (345x445)

Oval manway

A319 (345x445)

Oval manway

A320 (345x445)

Oval manway

A321 (345x445)

Rectangular manway

A362 (530x400)

Rectangular manway

A362V (530x400)

Rectangular manway

A362R (530x400)

Rectangular manway

A363 (400x530)

Rectangular manway

A363BV (400x530)

Rectangular manway

A363R (400x530)

Rectangular manway

A363V (400x530)