Stainless steel manway W4/C with PED certificate - key features

The W4/C round pressure manway is manufactured from stainless steel in AISI 304L (1.4307) grade, as well as AISI 316L (1.4404) for applications requiring greater resistance to environmental factors. The ranges of available sizes from DN220 to DN500, together with the pressure parameters, affect the ease of selection depending on the size of the tank.

The standard gaskets used in the manway are made of EPDM, however, other optional gasket materials significantly expand the spectrum of applications for the manway

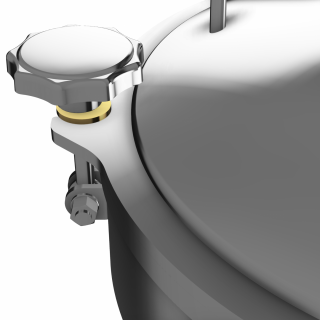

Aseptic closure

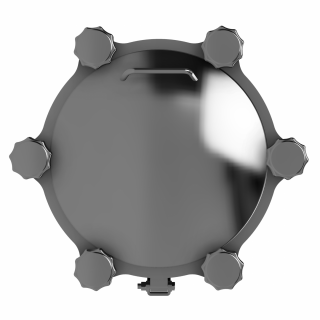

The solid closure of the manway cover, in the form of pressing elements permanently fitted to the tabs located on the edge of the cover, makes opening and closing the manway extremely comfortable.

At the same time, this solution reduces the deposition of dirt in the cover area, which ensures a higher level of hygiene of the manway.

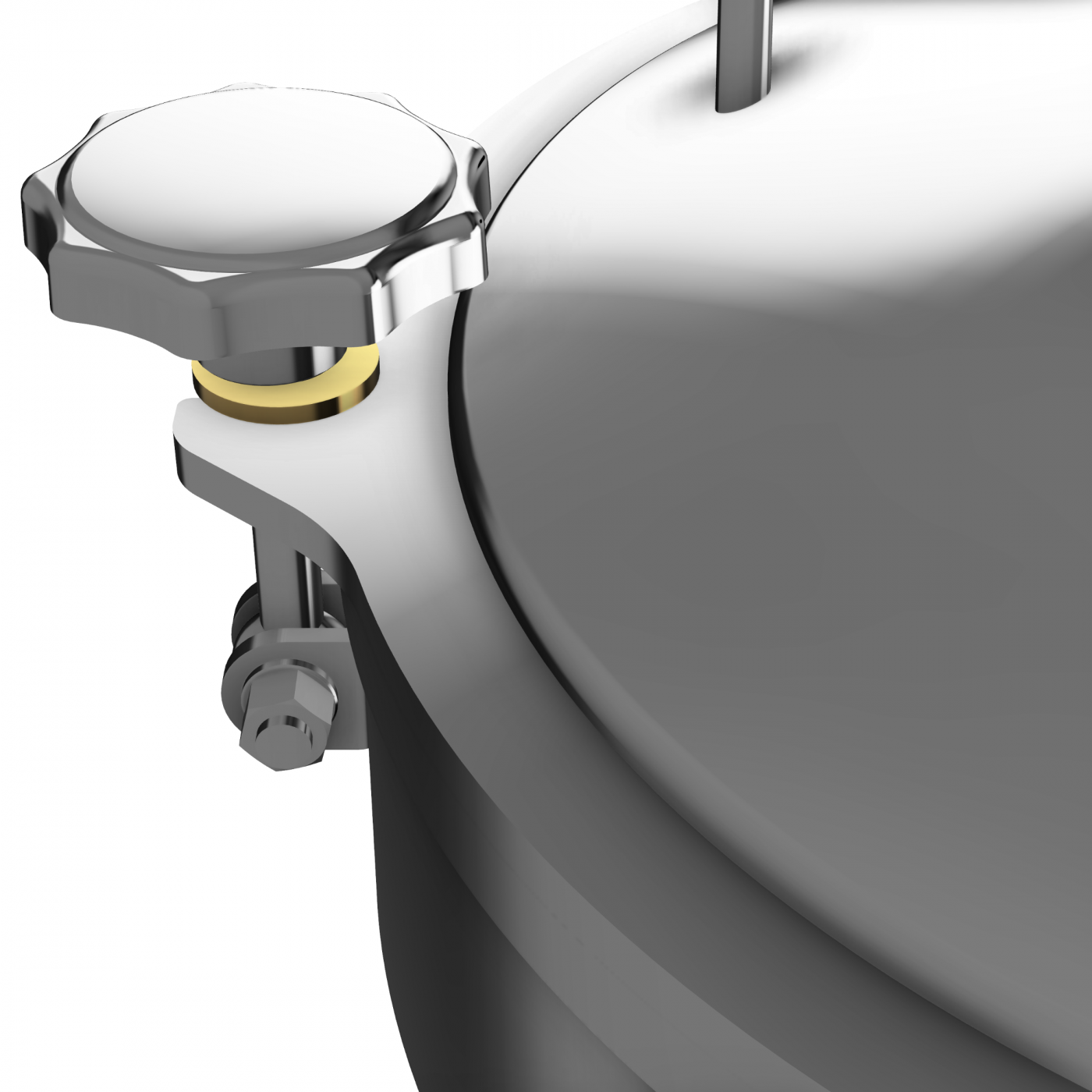

Pin handwheel fixing

The bolts of the handwheels are attached to the flange (frame) of the manway using solid pin closures.

This solution guarantees both the high strength of each manway closure and the ease and speed of replacing these components in the future.

Pressure resistance

The pressure resistance of the various versions of the W4/C manway depends primarily on the required diameter of the manway and the number of handwheels. All available configurations are shown in the "dimensions" tab.

The W4/C manway is manufactured in accordance with the guidelines of the PED Pressure Directive, which is confirmed by a certificate.

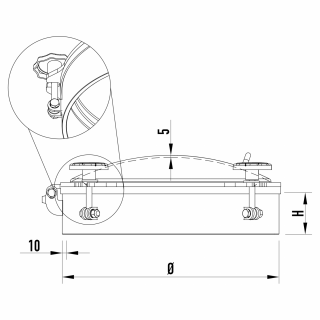

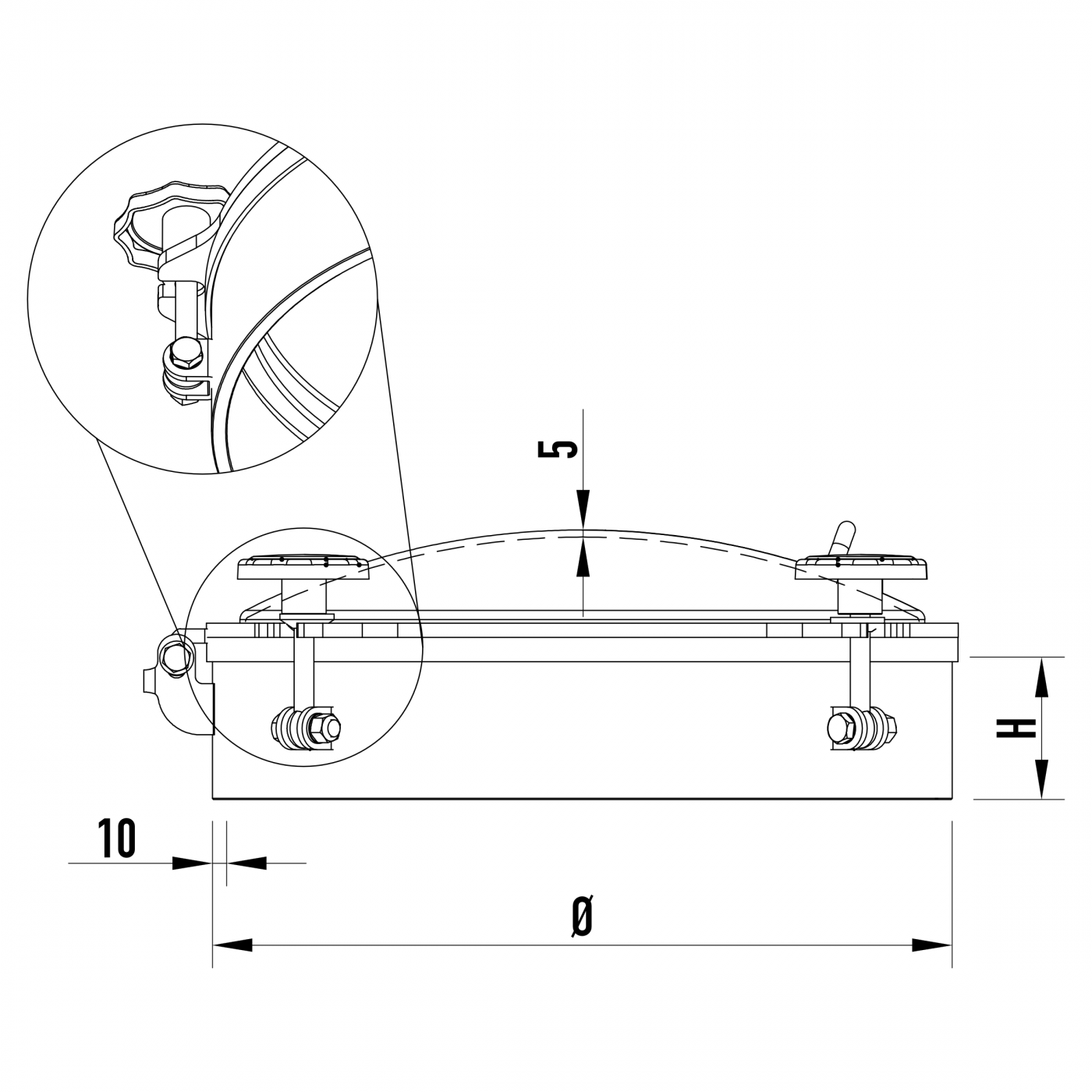

Lid and hinge

The convex shape of the cover and the polishing of its surface are designed to reduce the adhesion of dirt, and help liquids drain freely.

This advantage should be especially appreciated by those users who are forced to frequently clean process lines in order to maintain high hygienic standards.

The whole is completed by a hinge responsible for stabilizing the lid during opening and closing, as well as a handle to make this process easier.

Great features at a reasonable price

The W4/C round pressure manway can be successfully installed in the roofs of pressure vessels of various purposes. These can be stainless steel tanks used:

- in the food industry,

- in beverage production,

- in brewing,

- in equipment used in power generation, chemical industry and many others.

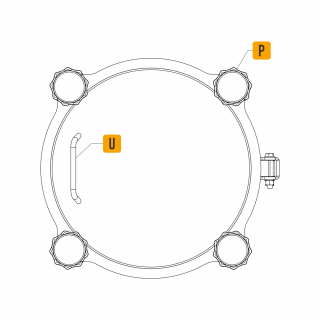

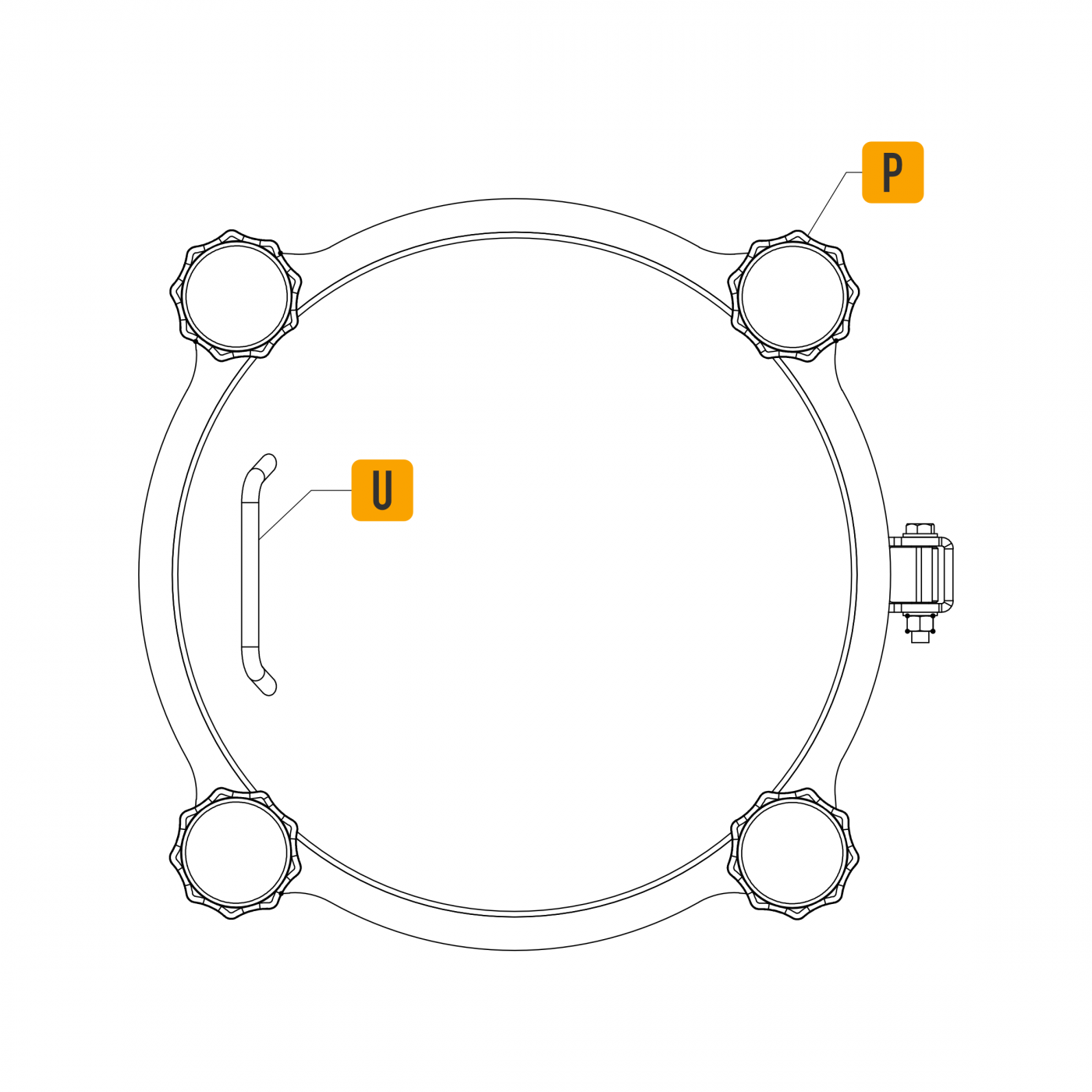

Manway elements

| Symbol | Element |

|---|---|

| P | handwheel |

| U | handle |

Table of dimensions

| Model | Ø [mm] |

H [mm] |

Handwheels* |

|---|---|---|---|

| W4/C/220 | 220 | 100 | 3 / 4 |

| W4/C/300 | 300 | 100 | 3 / 4 / 6 / 8 |

| W4/C/360 | 360 | 100 | 3 / 4 / 6 / 8 |

| W4/C/400 | 400 | 100 | 4 / 6 / 8 / 10 |

| W4/C/450 | 450 | 100 | 4 / 6 / 8 / 10 |

| W4/C/500 | 500 | 100 | 4 / 6 / 8 / 10 / 12 |

*The pressure resistance of the particular manhole is related to the number of handwheels (see below pressure resistance tables).

Pressure resistance

W4/C/220 (DN220)

| Handwheels | MAX (50-150°C) [bar] |

MAX |

MAX (201-250°C) [bar] |

|---|---|---|---|

| 3 | 5.5/-1.0 | 4.0/-1.0 | 3.8/-1.0 |

| 4 | 8.5/-1.0 | 6.0/-1.0 | 5.8/-1.0 |

W4/C/300 (DN300)

| Handwheels | MAX (50-150°C) [bar] |

MAX |

MAX (201-250°C) [bar] |

|---|---|---|---|

| 3 | 3.0/-1.0 | 2.0/-1.0 | 1.8/-1.0 |

| 4 | 5.5/-1.0 | 4.0/-1.0 | 3.6/-1.0 |

| 6 | 7.0/-1.0 | 5.0/-1.0 | 4.5/-1.0 |

| 8 | 8.5/-1.0 | 6.0/-1.0 | 5.0/-1.0 |

W4/C/360 (DN360)

| Handwheels | MAX (50-150°C) [bar] |

MAX |

MAX (201-250°C) [bar] |

|---|---|---|---|

| 3 | 2.5/-1.0 | 2.0/-1.0 | 1.8/-1.0 |

| 4 | 5.0/-1.0 | 4.0/-1.0 | 3.5/-1.0 |

| 6 | 6.2/-1.0 | 5.0/-1.0 | 4.5/-1.0 |

| 8 | 8.5/-1.0 | 6.0/-1.0 | 5.5/-1.0 |

W4/C/400 (DN400)

| Handwheels | MAX (50-150°C) [bar] |

MAX |

MAX (201-250°C) [bar] |

|---|---|---|---|

| 4 | 3.5/-1.0 | 2.6/-1.0 | 2.4/-1.0 |

| 6 | 6.0/-1.0 | 5.1/-1.0 | 4.7/-1.0 |

| 8 | 8.0/-1.0 | 6.4/-1.0 | 5.7/-1.0 |

| 10 | 10.0/-1.0 | 8.0/-1.0 | 7.0/-1.0 |

W4/C/450 (DN450)

| Handwheels | MAX (50-150°C) [bar] |

MAX |

MAX (201-250°C) [bar] |

|---|---|---|---|

| 4 | 3.0/-1.0 | 2.0/-1.0 | 1.8/-1.0 |

| 6 | 6.0/-1.0 | 4.0/-1.0 | 3.1/-1.0 |

| 8 | 7.5/-1.0 | 5.5/-1.0 | 4.5/-1.0 |

| 10 | 9.0/-1.0 | 6.0/-1.0 | 5.0/-1.0 |

W4/C/500 (DN500)

| Handwheels | MAX (50-150°C) [bar] |

MAX |

MAX (201-250°C) [bar] |

|---|---|---|---|

| 4 | 2.0/-1.0 | 1.5/-1.0 | 1.3/-1.0 |

| 6 | 4.5/-1.0 | 4.0/-1.0 | 3.5/-1.0 |

| 8 | 6.5/-1.0 | 5.7/-1.0 | 4.5/-1.0 |

| 10 | 8.0/-1.0 | 6.5/-1.0 | 5.7/-1.0 |

| 12 | 10.0/-1.0 | 7.0/-1.0 | 6.5/-1.0 |

Technical parameters

| Product series | Series W |

|---|---|

| Shape | Round manways |

| Type | Pressure manway |

| Frame height (in mm) | 100 mm |

| Frame wall thickness (in mm) | 10.0 mm |

| Industry | Brewing, Chemical, Dairy, Food production, Pharmaceutical |

| Size | below DN300, DN300 - DN500 |

| Mounting method | in the tank roof (top manways) |

| Pressure | 0.5 - 2.5 bar, 2.51 - 4.5 bar, 4.51 - 6.5 bar, 6.51 - 8.5 bar, above 8.5 bar |

| Vacuum pressure | up to -0.5 bar, from -0.51 to -1.0 bar |

| PED certificate | yes |

| Steel grade | AISI 304/304L, AISI 316/316L |

| Gasket material | EPDM, NBR, Silicone, Viton |

| Handwheel material | INOX |