A stainless steel manway is an integral part of most beer vats and tanks. The frequency of use and the parameters of the processes occurring during beer production require stainless steel manways to be exceptionally durable, pressure resistant, but also aesthetically pleasing – after all, the interior of a brewery is often its showpiece, open to frequent visits by guests.

What kind of manways can be found in a brewery? In what units are they installed? And finally – what to keep in mind when choosing the right manway for brewery tanks?

In general, brewing uses manways in all available shapes – round, oval and rectangular. However, there are fairly common procedures regarding their use. This is because different types of manways are used in the various tanks used in the brewery.

Beer vats and other tanks that do not have elevated operating pressure usually use non-pressure round manways. However, the operating temperature remains an important parameter for this type of tank, often oscillating around 100°C – this has a significant impact on the selection of the manway gasket material, which is usually EPDM.

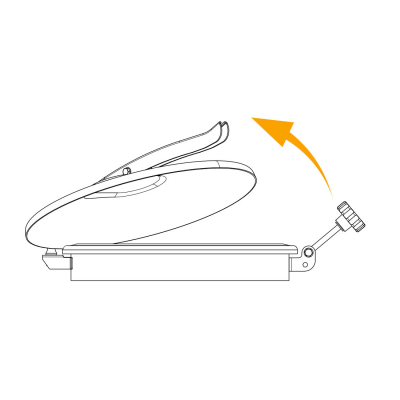

Round manways for beer vats often have another important feature – the ability to tilt the cover to the side. This is because in the case of manways with a sideways sliding cover, there is no need to perpendicularly lift the entire cover each time and make a full 180° arc movement – it is enough only to loosen the handwheel and gently lift the cover to push it back in the desired direction. Thus, this solution even allows the opening to be partially covered while ongoing work is being carried out with the tank (such as adding an ingredient to the production).

A group of manways that is particularly popular among brewers are those with a glass (see-through) cover. This solution allows constant visual inspection of the medium in the tank. The glass used in these types of manways is usually characterised by a temperature resistance of up to 120°C, and depending on the version, manways with a glass cover can come in a non-pressure or pressure option (resistance up to a maximum of 2.0 bar).

Round manway

Round manway

Rectangular manways in breweries are most often used to cover the side inspection opening of beer vats. Thus, they enable both sufficient technical inspection and cleaning of the tank as well as ongoing maintenance. In the case of beer vats, the most common types of rectangular manways are those with dimensions of about 400x300 mm and 400x530 mm.

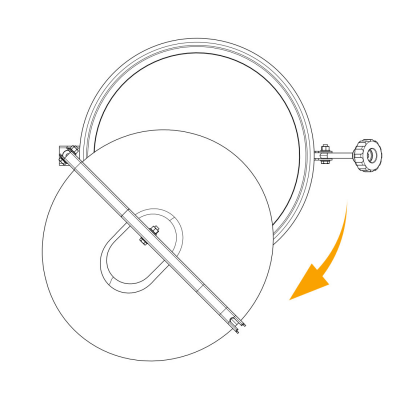

An important group of manways for brewing includes pressure manways. Oval manways are usually used to close the side inspection opening in CKT and BBT tanks. Round manways, on the other hand, are used as the top inspection component of the same tanks.

Oval manways used in the production of beer are usually characterised by a pressure resistance of up to 3.0 bar and are mounted in the side shell of tanks. The group of pressure oval manways includes:

models with standard mounting frame,

versions arched to the diameter of the tank.

A group of oval manways arched to the curvature of the tank is particularly desirable for breweries. This is because they provide an highly aesthetically pleasing appearance to the CKT and BBT tanks, and thus affect the overall visual perception of the brewery's interior.

Pressure round manways in CKT and BBT tanks are used both as an additional inspection element (complementary to side oval manways) or as an alternative to the side inspection opening. Their installation takes place in the roof (top head) of pressure tanks, while their pressure resistance (similar to that of oval manways) is usually 3.0 bar.

We use cookies