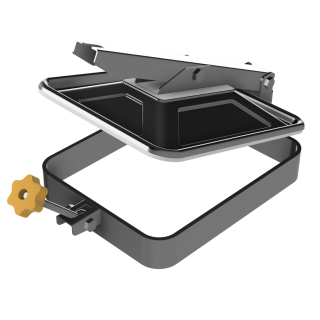

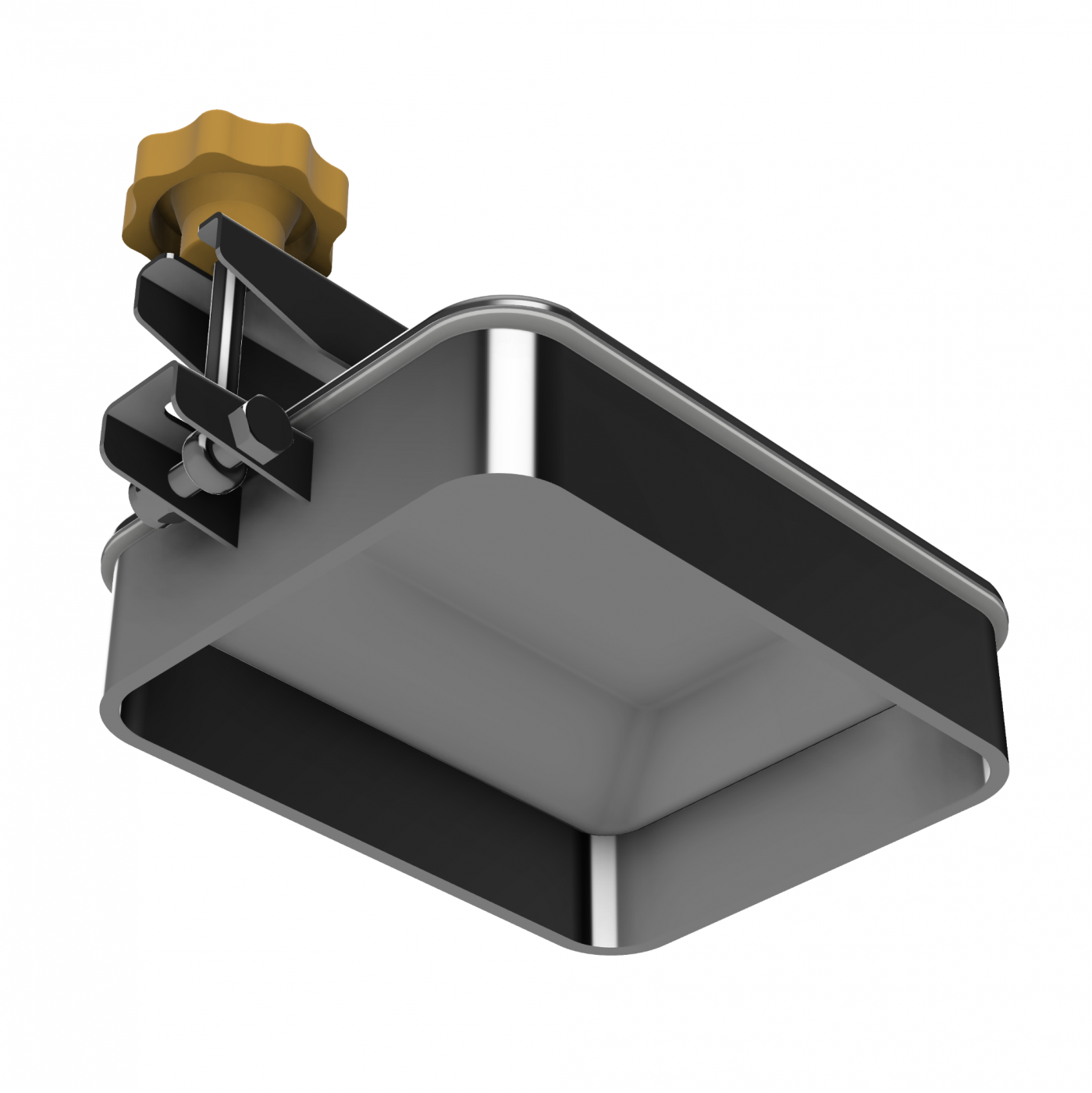

Stainless steel manway W2/F - key features

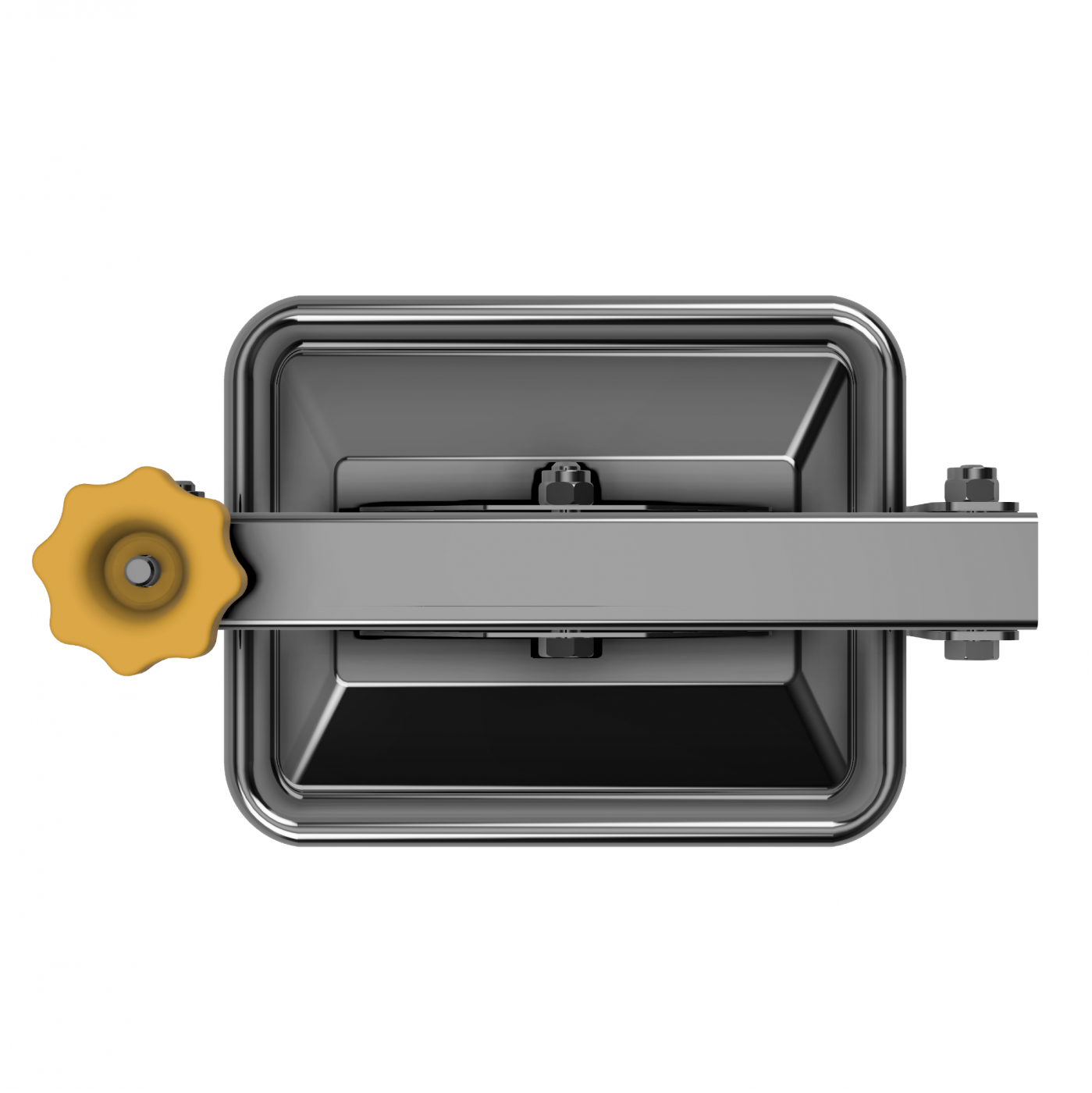

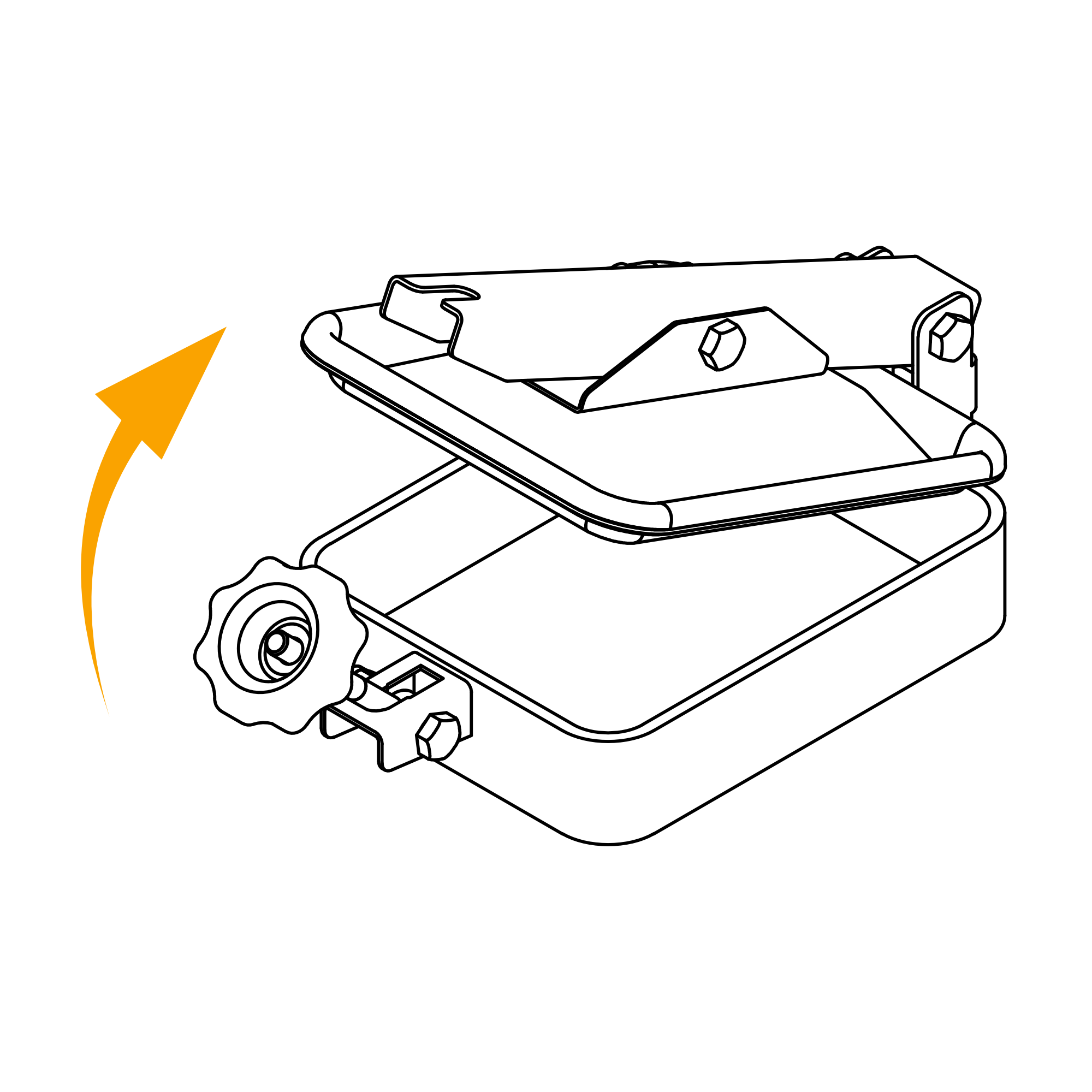

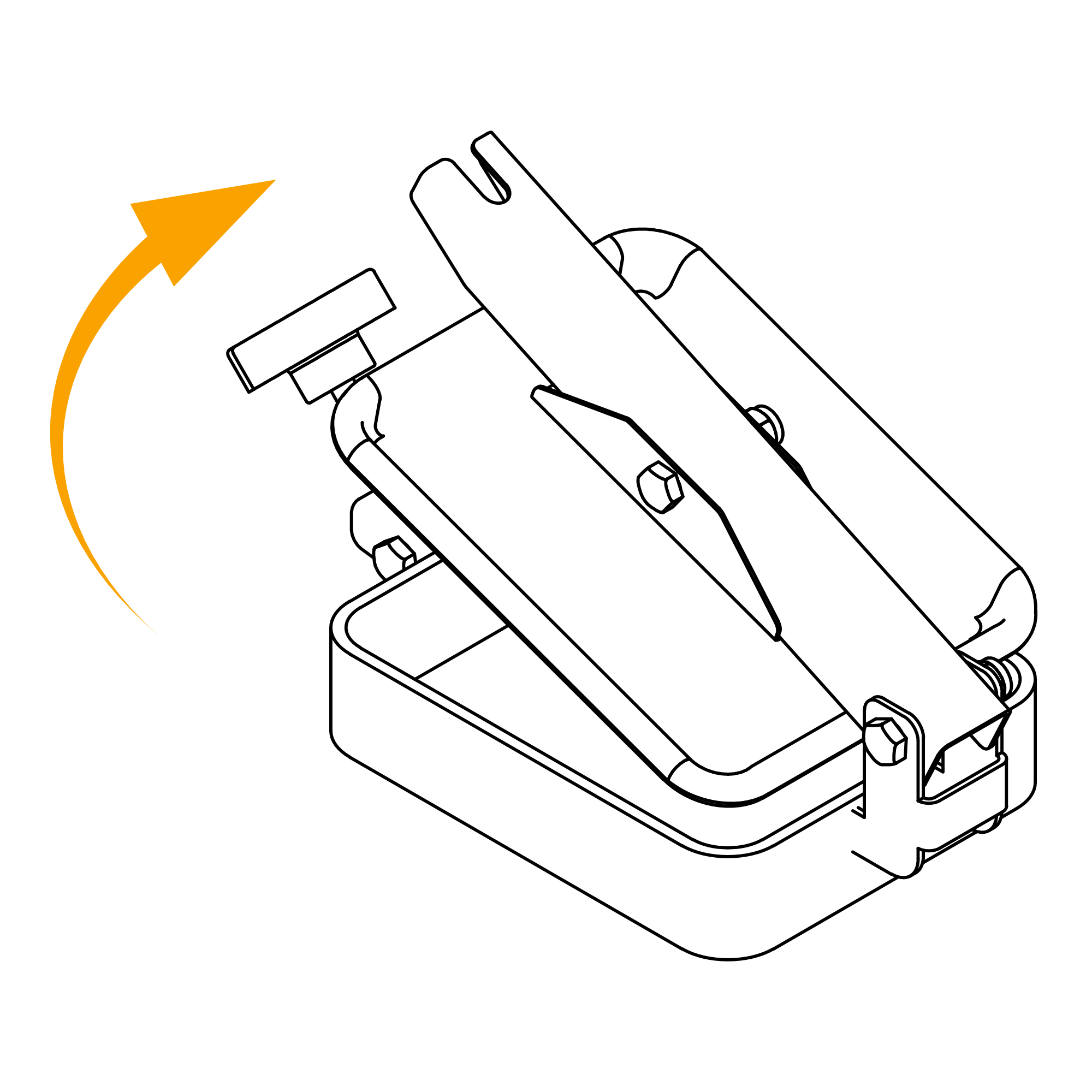

The W2/E stainless steel rectangular manway cover can be installed in the side wall or roof of a stainless steel non-pressure tank. The hinged lid opens outwards and is tightened by means of a handwheel. As standard, the manhole is equipped with an EPDM gasket and a plastic handwheel.

The color of the handwheel may be different from that shown in the photos.

The use of rectangular manway W2/F

The small dimensions and compact design allow the W2/F rectangular manway to be installed not only in tanks, but also in various types of gastronomic equipment made of stainless steel. Therefore, the natural working environment for this model is food production facilities, including dairies, distilleries, manufacturers of concentrates and related products.

Nothing prevents its successful use in other industries as well - including:

- chemical industry,

- cosmetics industry,

- biotech industry.

It can also be used by manufacturers of small tanks, cisterns and distillers, as well as many other machines and equipment in their products. When planning the use of this type of manway in a specific application, it is essential to consider the properties of the materials used in its construction to avoid problems with corrosion and resistance to temperature, and chemical factors.

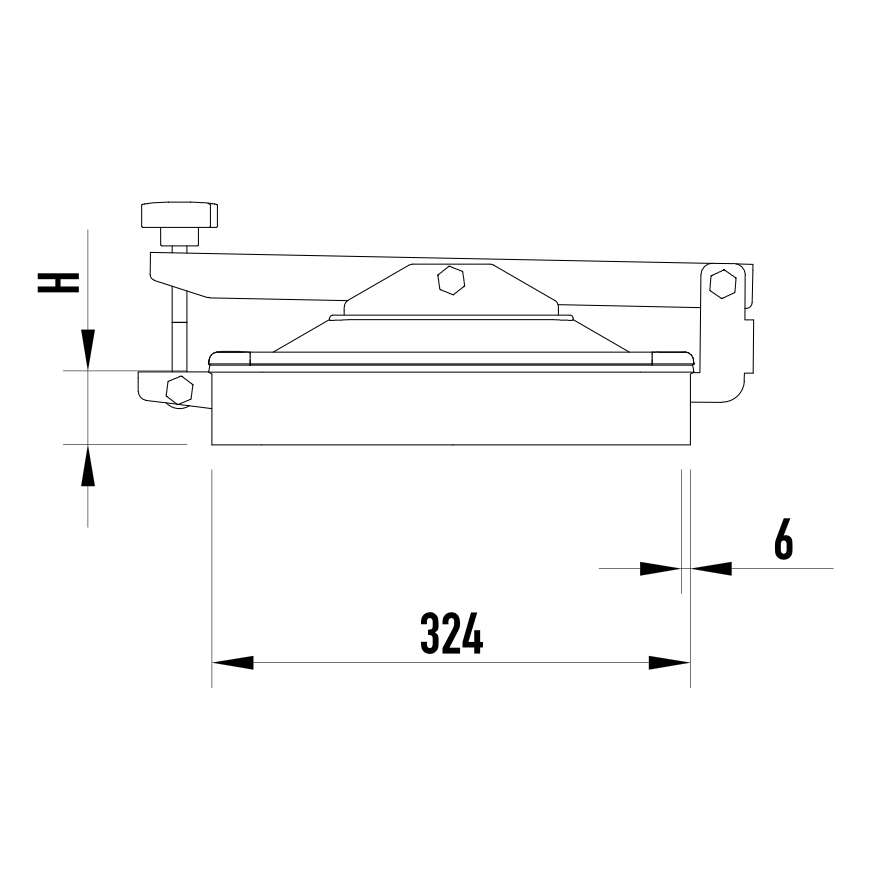

| Model | H [mm] | MAX [bar] |

|---|---|---|

| W2/F |

30 50 (standard) 100 |

0.5 |

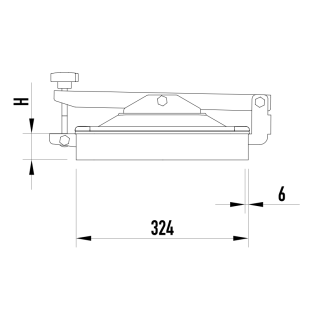

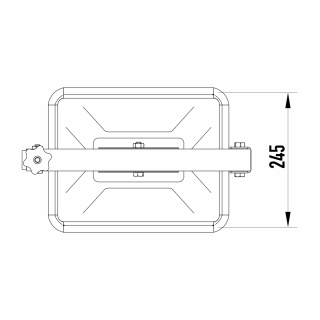

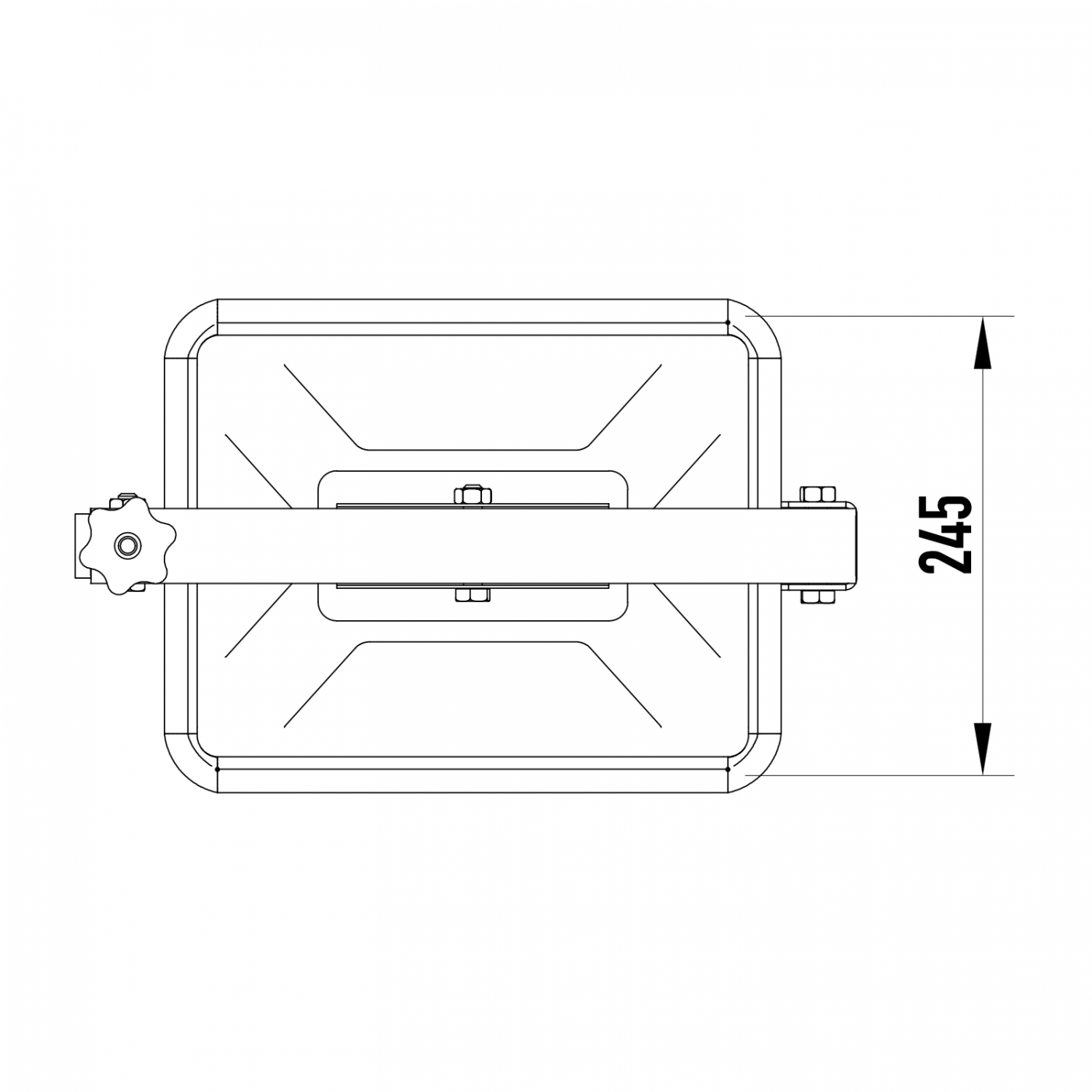

Technical parameters

| Product series | Series W |

|---|---|

| Size | M (longer manway side between 300-500 mm) |

| Shape | Rectangular manways |

| Type | Non-pressure manway |

| Frame height (in mm) | 30-100 mm |

| Frame wall thickness (in mm) | 6.0 mm |

| Opening type | Outward |

| Industry | Brewing, Chemical, Dairy, Food production, Winemaking |

| Mounting method | in the tank roof (top manways), in the tank side wall (side manways) |

| Pressure | 0.5 - 2.5 bar |

| Vacuum pressure | not applicable |

| PED certificate | no |

| Steel grade | AISI 304/304L, AISI 316/316L |

| Gasket material | EPDM, NBR, Neoprene, Silicone, Viton |

| Handwheel material | Plastic, INOX |