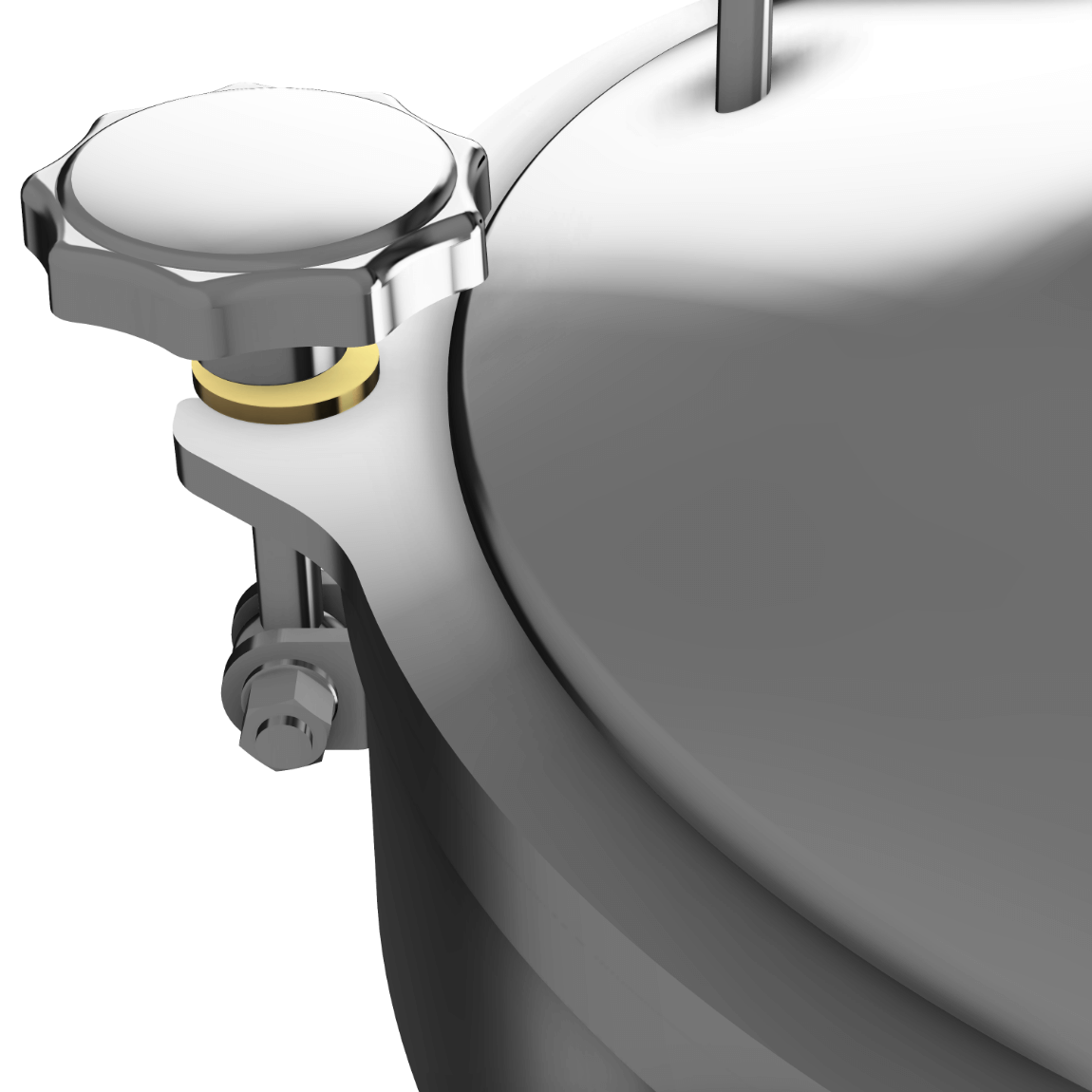

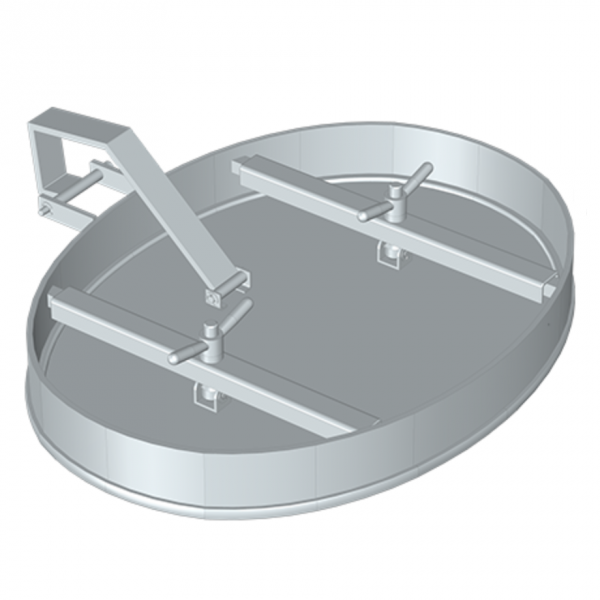

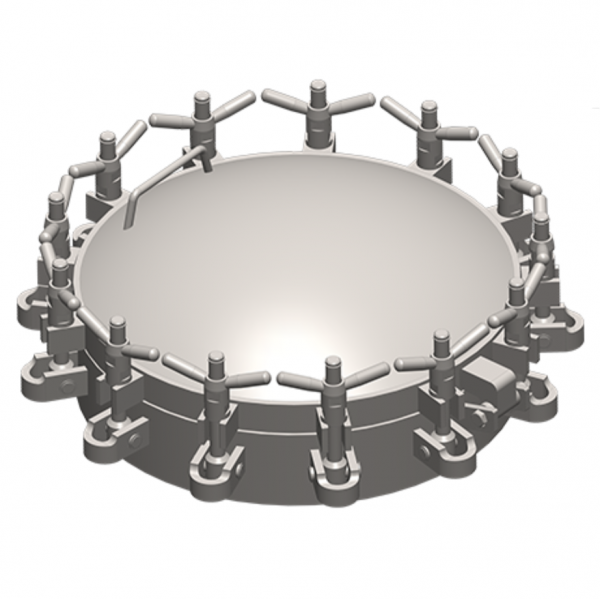

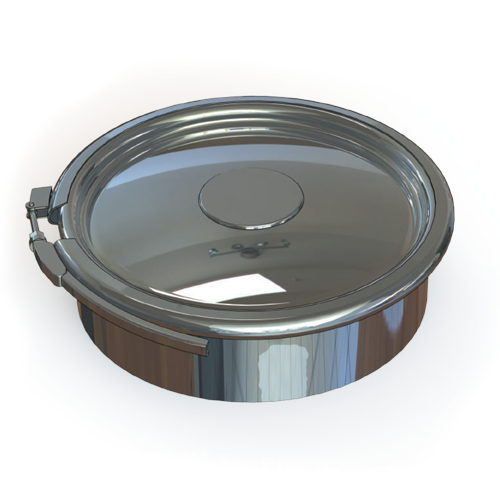

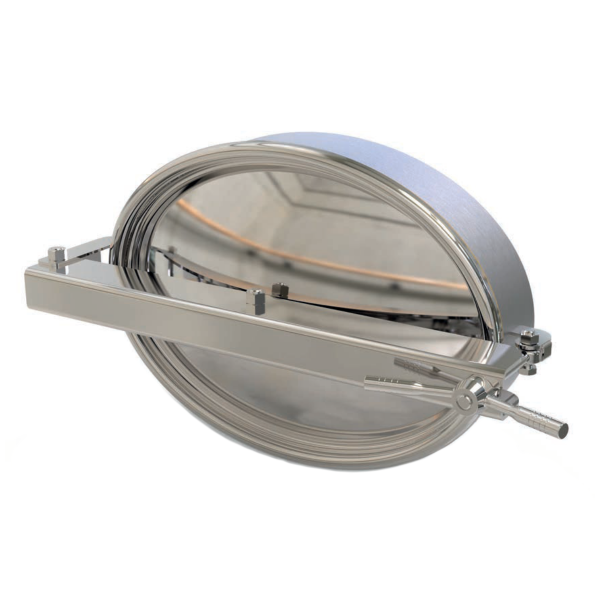

Round manway

W4/A (DN220-DN500)

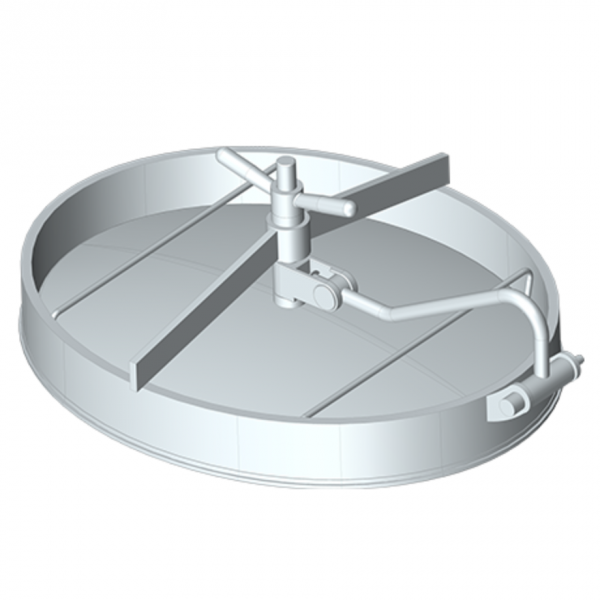

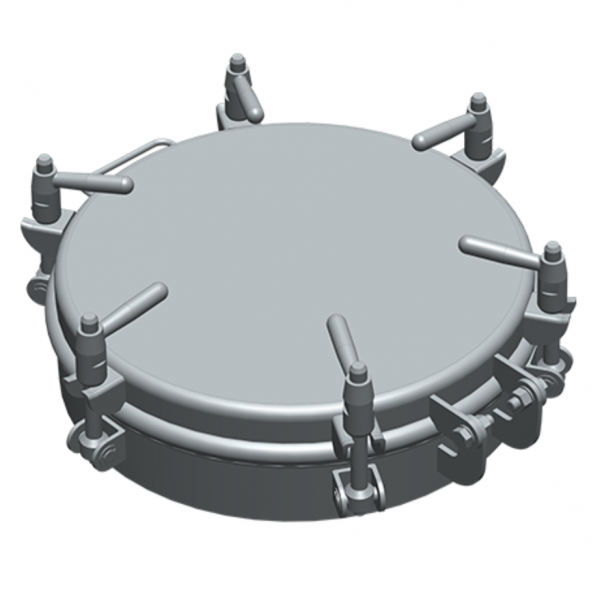

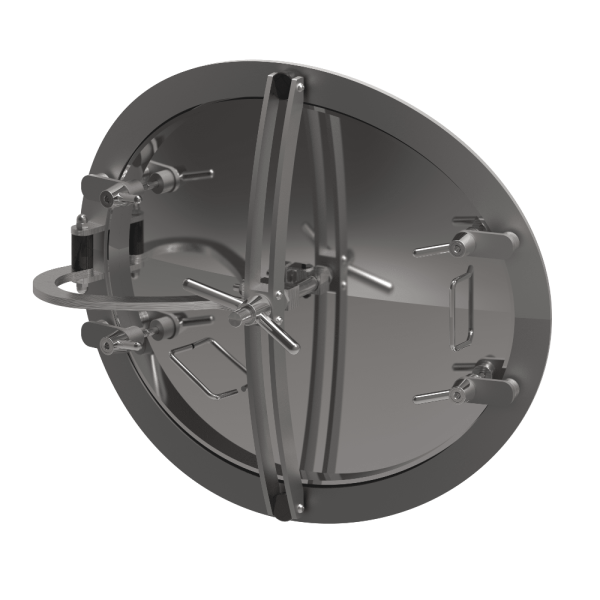

Round manway

W4/B (DN220-DN500)

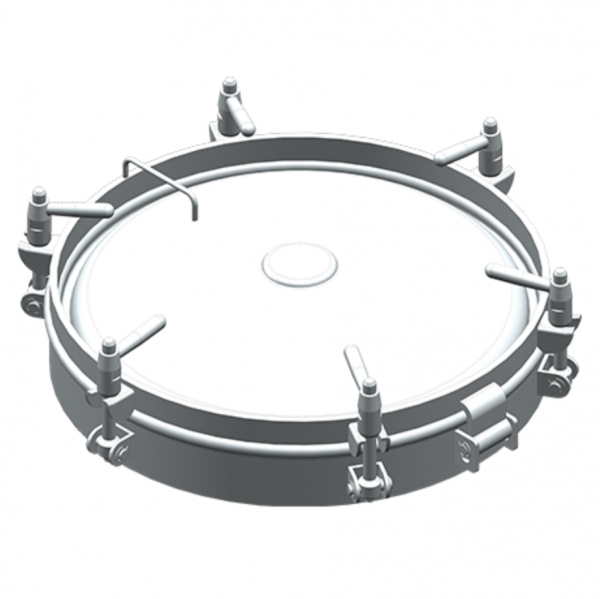

Round manway

W4/C (DN220-DN500)

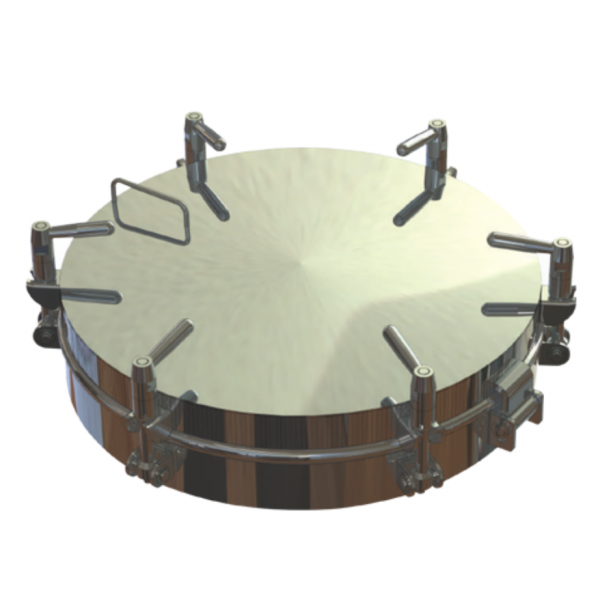

Round manway

W4/D (DN220-DN500)

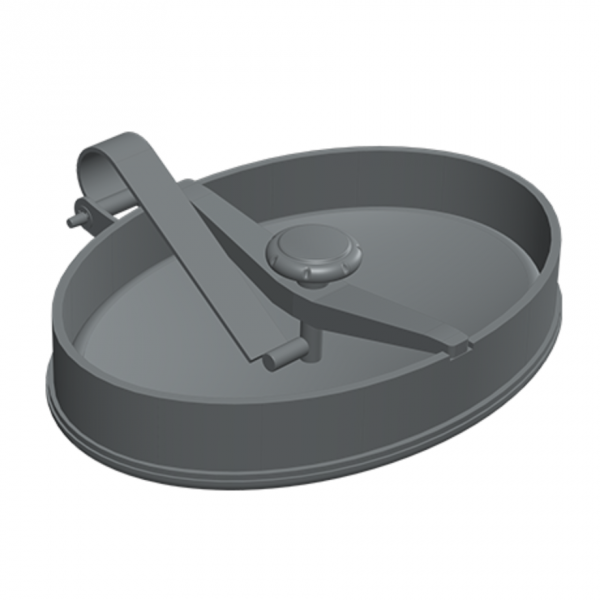

Oval manway

E125XL (550x450)

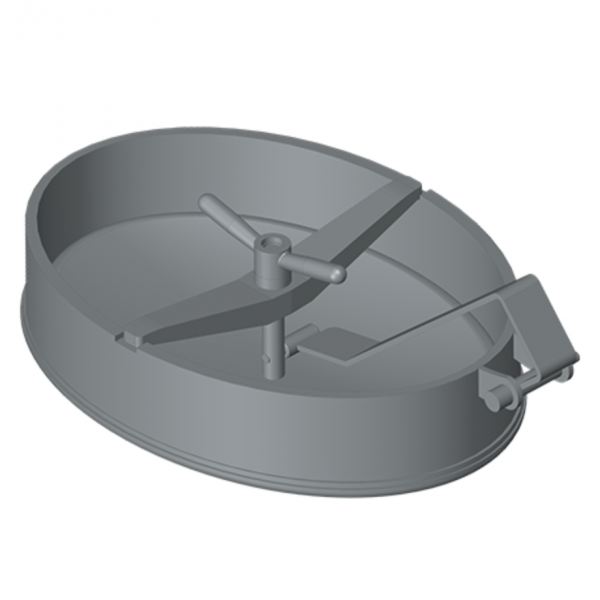

Oval manway

E126 (340x450)

Oval manway

E126/1 (440x340)

Oval manway

E126RS (440x340)

Oval manway

E128RS (440x308)

Oval manway

E127 (440x308)

Oval manway

E127/1 (444x312)

Oval manway

E128T (440x308)

Oval manway

E128TS (440x308)

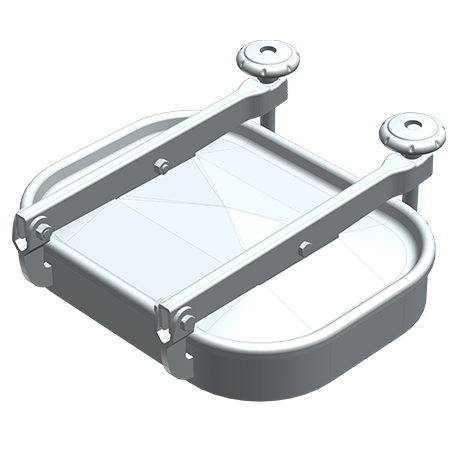

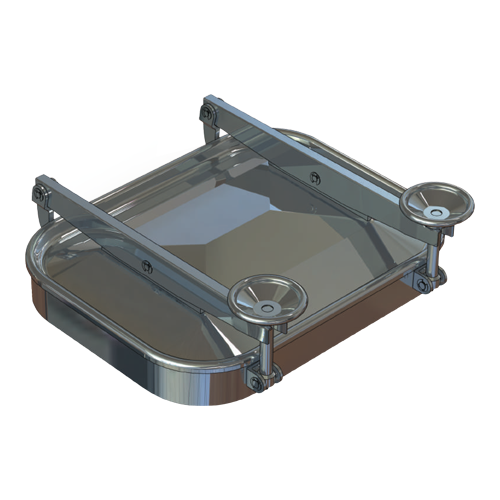

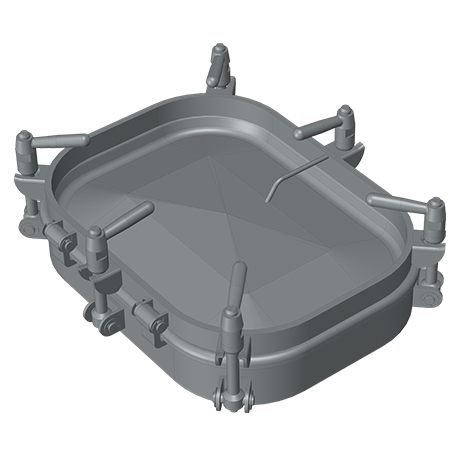

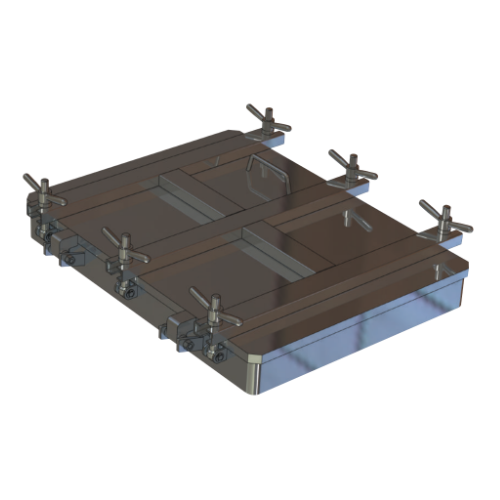

Rectangular manway

E129 (530x406)

Rectangular manway

E130 (424x316)

Rectangular manway

E131 (424x316)

Rectangular manway

E132 (450x750)

Rectangular manway

E133 (600x800)

Oval manway

E156 (540x410)

Oval manway

E158 (440x308)

Rectangular manway

E134 (600x800)

Rectangular manway

E135 (800x1000)

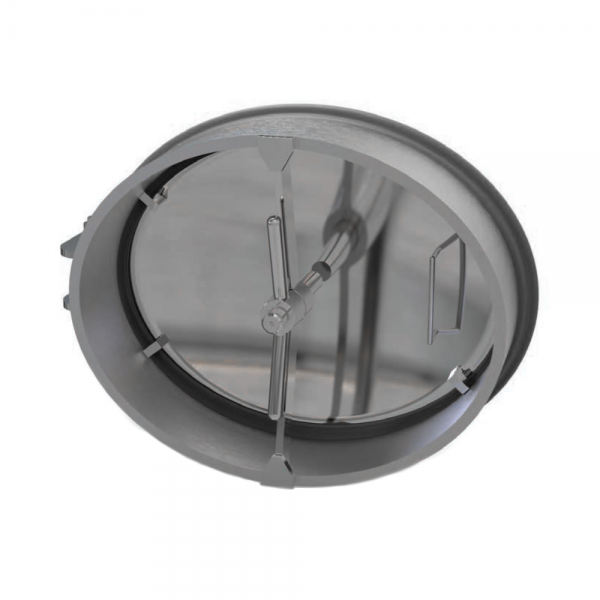

Round manway

A520 (DN200-DN600)

Round manway

A800R (DN380-DN420)

Oval manway

A304 (305x430)

Oval manway

A306 (305x430)

Oval manway

A307 (305x430)

Oval manway

A308 (345x445)

Oval manway

A309 (345x445)

Oval manway

A309IG (345x445)

Oval manway

A310 (400x490)

Oval manway

A312 (305x430)

Oval manway

A314 (400x490)

Oval manway

A315 (400x490)

Oval manway

A316 (345x445)

Oval manway

A317 (345x445)

Oval manway

A317E (345x445)

Oval manway

A318 (345x445)

Oval manway

A319 (345x445)

Oval manway

A320 (345x445)

Oval manway

A321 (345x445)

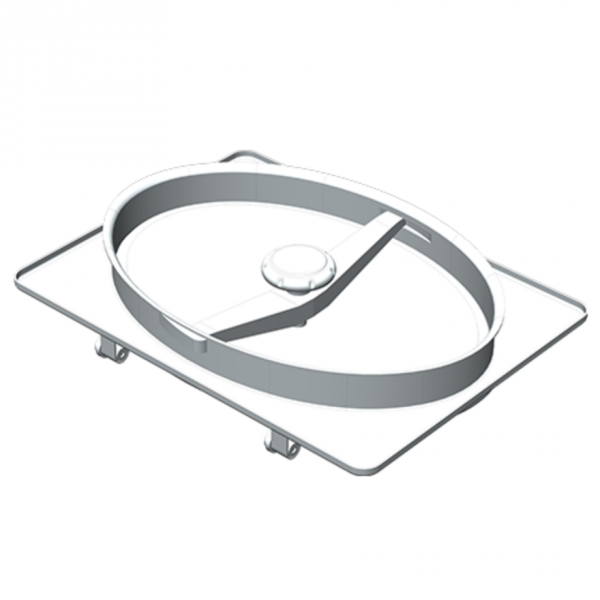

Rectangular manway

A362 (530x400)

Rectangular manway

A362V (530x400)

Rectangular manway

A362R (530x400)

Rectangular manway

A363 (400x530)

Rectangular manway

A363R (400x530)

Rectangular manway

A364 (530x400)

Oval manway

E125 (410x510)

Oval manway

E128 (440x308)

Oval manway

E128/1 (444x312)

Rectangular manway

A374 (420x310)

Rectangular manway

E129/1 (530x406)

Oval manway

P11-101 (307x442)

Rectangular manway

P13-105 (314x424)

Rectangular manway

P13-409 (410x534)

Oval manway

P11-102 (442x307)

Oval manway

P11-302 (442x307)

Oval manway

P11-129 (407x452 / 411x455)

Oval manway

P11-340-440ED (340x440)

Oval manway

P11-410-510 (410x510)

Oval manway

P11-608 (600x800)

Round manway

P12-510 (DN504-DN800)

Round manway

P22-238 (DN204-DN400)

Round manway

P22-265 (DN504-DN604)

Round manway

P22-265ATR (DN504)

Round manway

P22-800 (DN800)

Round manway

P22-233 (DN204-DN400)

Round manway

P22-443 (DN457-DN600)

Rectangular manway

P23-210 (314x424)

Rectangular manway

P23-111 (410x534)

Rectangular manway

P23-201 (314x424 / 410x534)

Round manway

BP420-490 (DN427-DN495)

Round manway

B150 (DN154-DN495)

Round manway

B150SC (DN154-DN495)

Round manway

B300PV (DN308-DN608)

Rectangular manway

P23-680 (600x800)

Oval manway

P21-147 (411x455)

Round manway

P32-305 (DN300-DN600)

Oval manway

P41-040 (305x440)

Round manway

C47 (DN300-DN600)

Rectangular manway

P43-012 (405x530 / 420x310)

Oval manway

C19 (440x310)

Oval manway

C49 (440x350)

Oval manway

C50 (440x350)

Oval manway

C52 (480x370)

Oval manway

C13 (310x440)

Round manway

K-MC (DN600-DN800)

Round manway

K-PC (DN50-DN300)

Round manway

X10324MT (DN500-DN600)

Round manway

X3348MT (DN200)

Oval manway

A324IG (550x650)