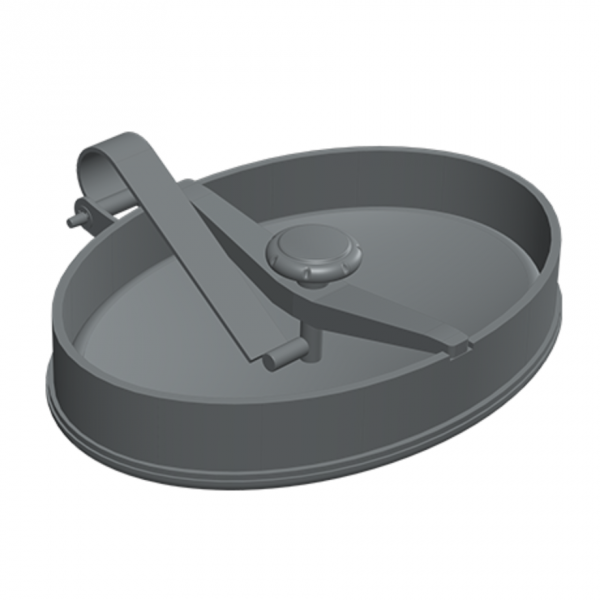

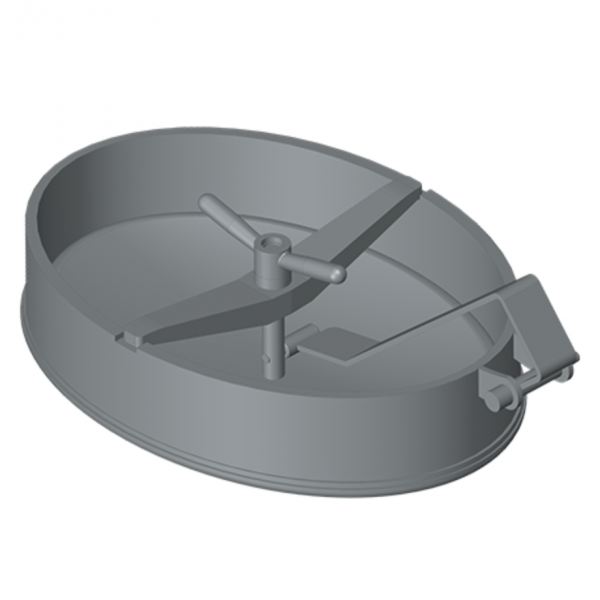

Oval manway

Oval manway

Oval manway

Oval manway

Oval manway

Oval manway

Oval manway

Oval manway

Oval manway

Oval manway

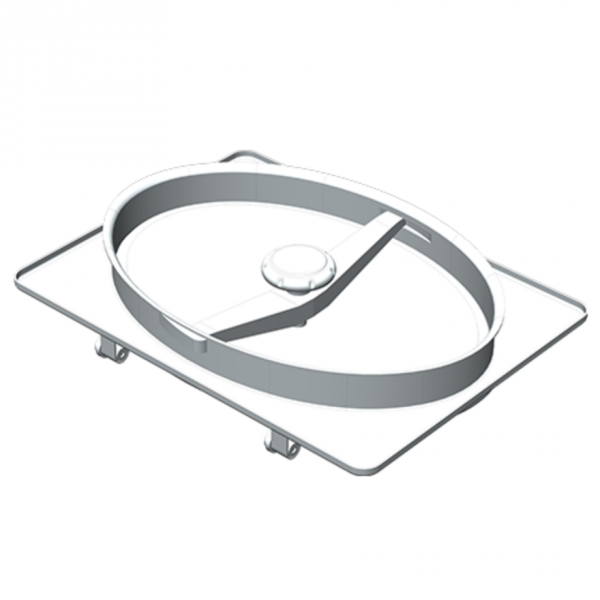

Rectangular manway

Rectangular manway

Rectangular manway

Oval manway

Oval manway

Oval manway

Oval manway

Oval manway

Oval manway

Oval manway

Oval manway

Oval manway

Oval manway

Oval manway

Oval manway

Oval manway

Oval manway

Oval manway

Oval manway

Oval manway

Oval manway

Rectangular manway

Oval manway

Oval manway

Oval manway

Rectangular manway

Rectangular manway

Special-purpose manway

Special-purpose manway

Oval manway

Rectangular manway

Rectangular manway

Oval manway

Oval manway

Oval manway

Oval manway

Oval manway

Oval manway

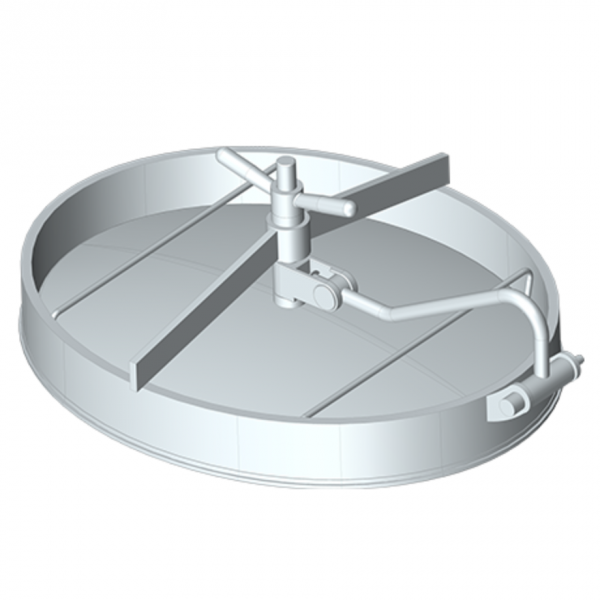

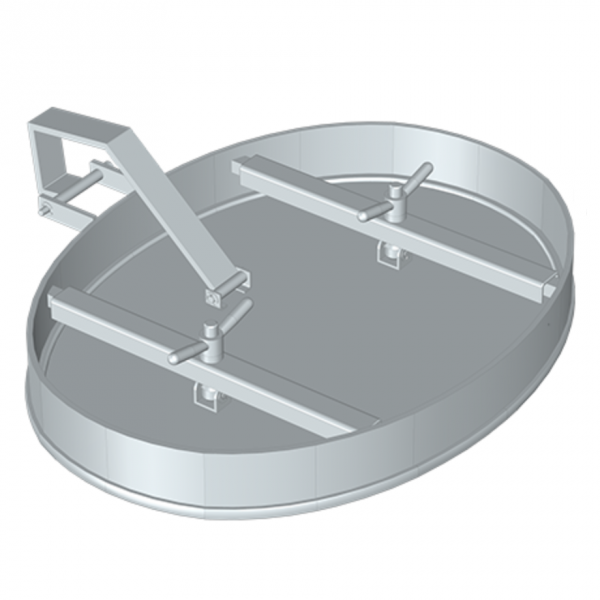

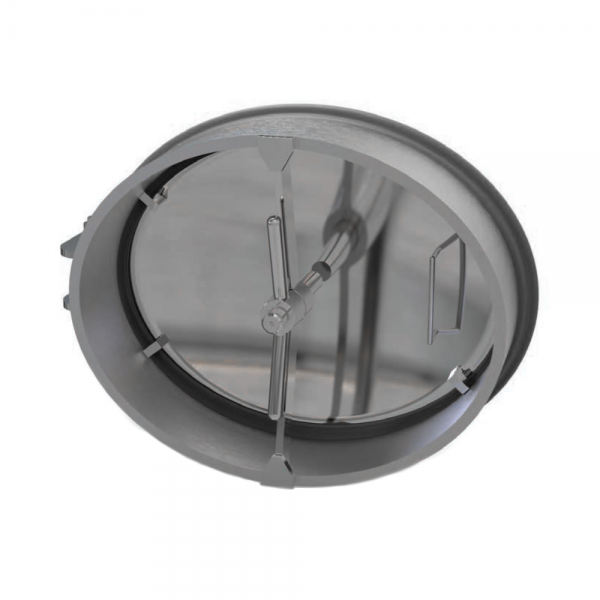

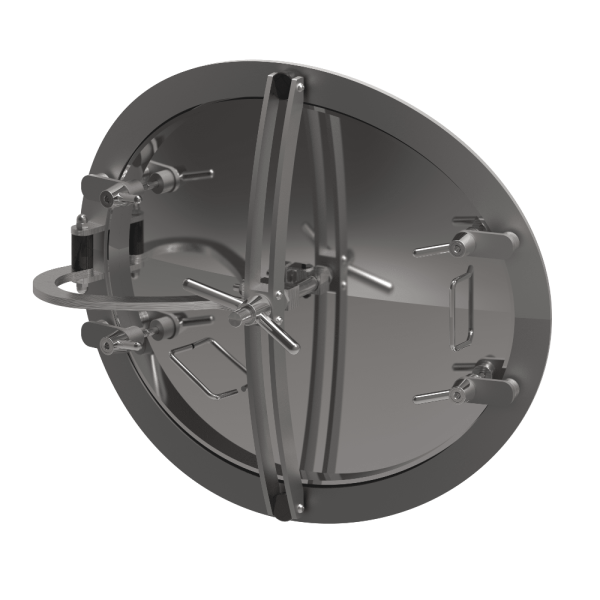

Round manway

Oval manway

Rectangular manway

Oval manway

Oval manway

Oval manway

Oval manway

Round manway

Special-purpose manway

Oval manway