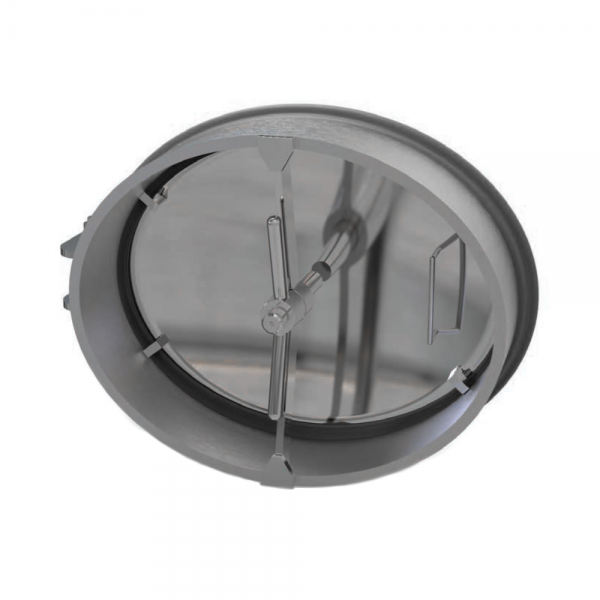

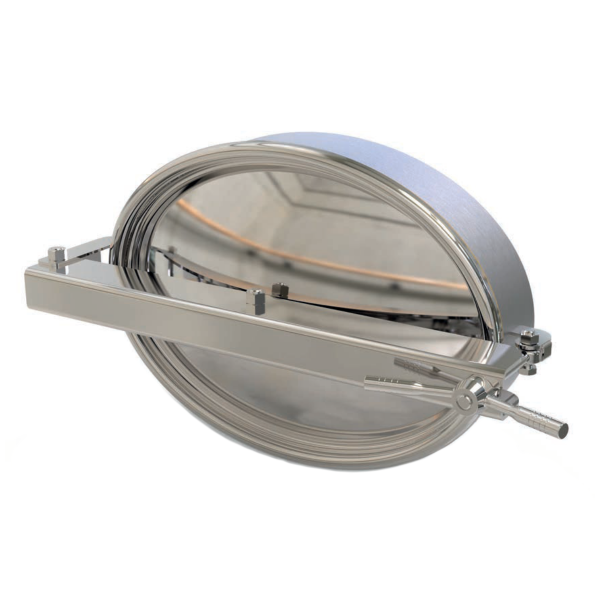

Oval manways with sides with a maximum length of 300-500 mm. The widest group of oval manways made of stainless steel AISI 304/304L and AISI 316/316L.

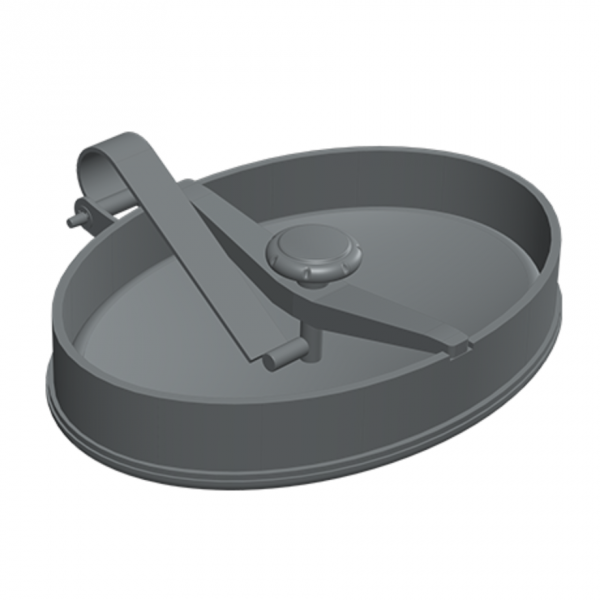

Oval manway

W3/F (440x308)

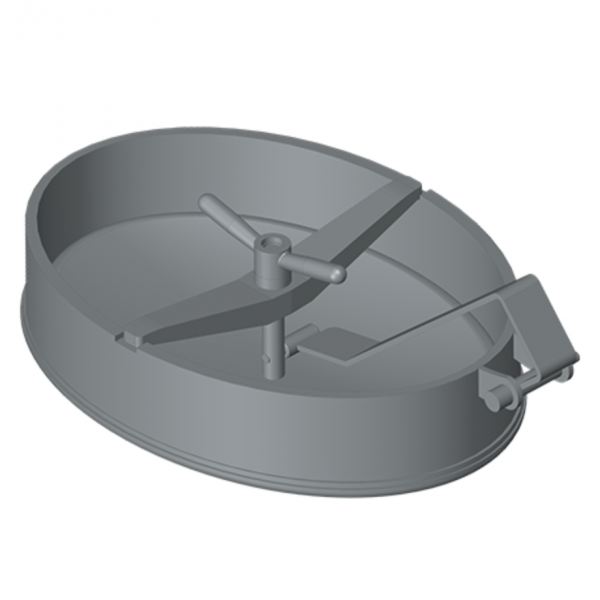

Oval manway

E126 (340x450)

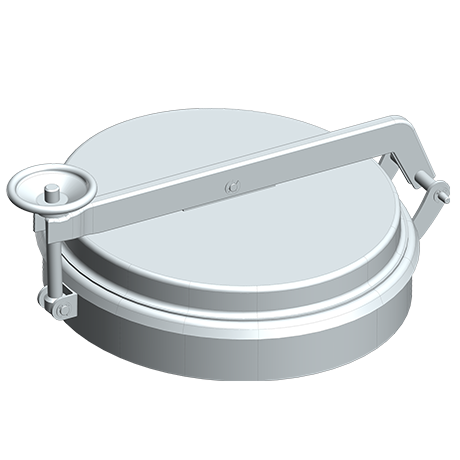

Oval manway

E126/1 (440x340)

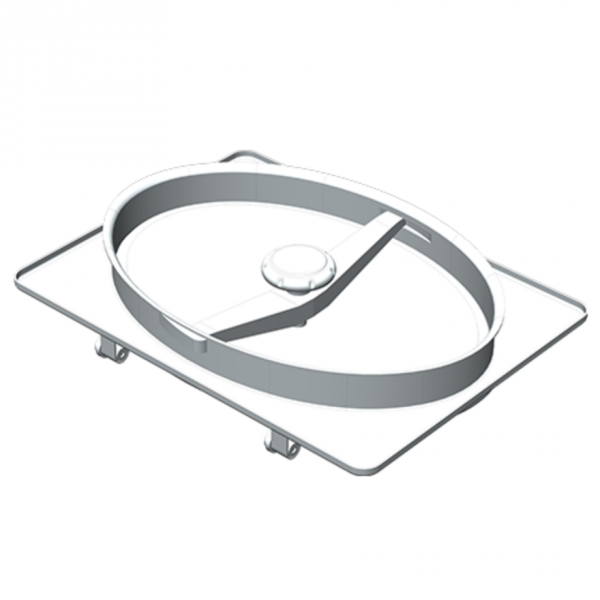

Oval manway

E126RS (440x340)

Oval manway

E128RS (440x308)

Oval manway

E127 (440x308)

Oval manway

E128T (440x308)

Oval manway

E128TS (440x308)

Oval manway

E157 (440x308)

Oval manway

E158 (440x308)

Oval manway

A304 (305x430)

Oval manway

A306 (305x430)

Oval manway

A307 (305x430)

Oval manway

A308 (345x445)

Oval manway

A309 (345x445)

Oval manway

A309IG (345x445)

Oval manway

A310 (400x490)

Oval manway

A311 (305x430)

Oval manway

A311G (305x430)

Oval manway

A312 (305x430)

Oval manway

A314 (400x490)

Oval manway

A315 (400x490)

Oval manway

A316 (345x445)

Oval manway

A317 (345x445)

Oval manway

A317E (345x445)

Oval manway

A318 (345x445)

Oval manway

A319 (345x445)

Oval manway

A320 (345x445)

Oval manway

A321 (345x445)

Oval manway

E128 (440x308)

Oval manway

E128/1 (444x312)

Oval manway

P11-101 (307x442)

Oval manway

P11-102 (442x307)

Oval manway

P11-302 (442x307)

Oval manway

P11-129 (407x452 / 411x455)

Oval manway

P11-340-440ED (340x440)

Oval manway

P21-303 (307x442)

Oval manway

P21-503 (307x442)

Oval manway

P21-116 (411x455)

Oval manway

P21-516 (411x455)

Oval manway

P21-147 (411x455)

Oval manway

P41-040 (305x440)

Oval manway

C19 (440x310)

Oval manway

C49 (440x350)

Oval manway

C50 (440x350)

Oval manway

C52 (480x370)

Oval manway

C13 (310x440)