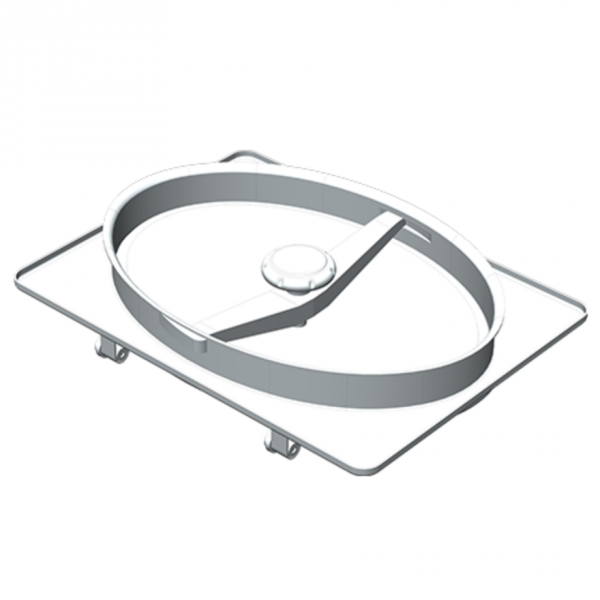

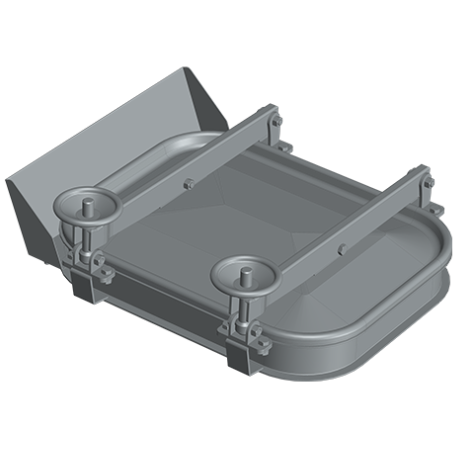

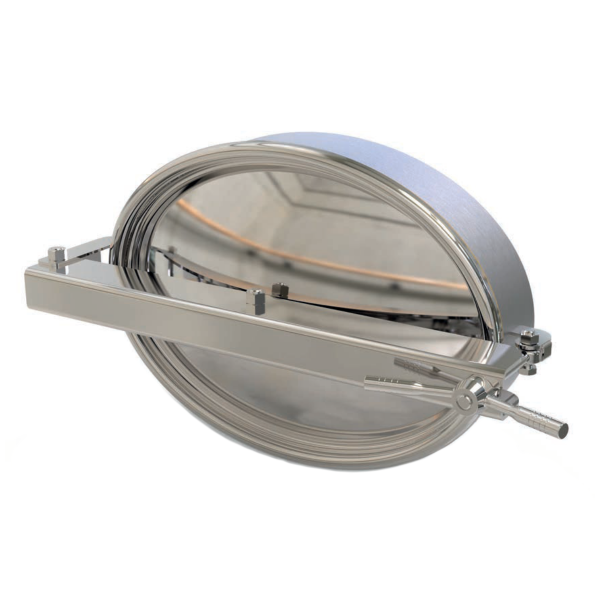

Oval manway

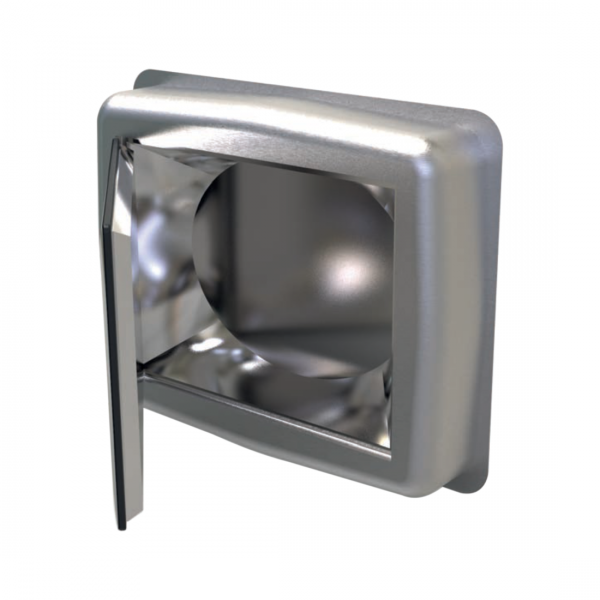

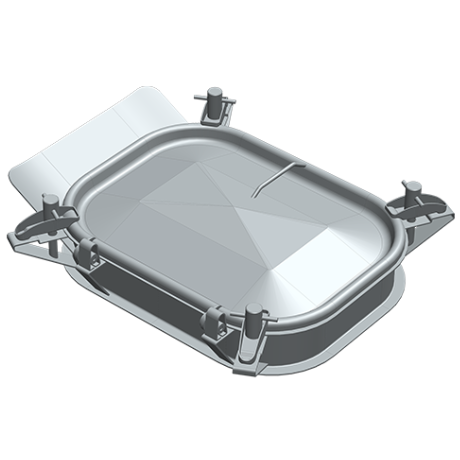

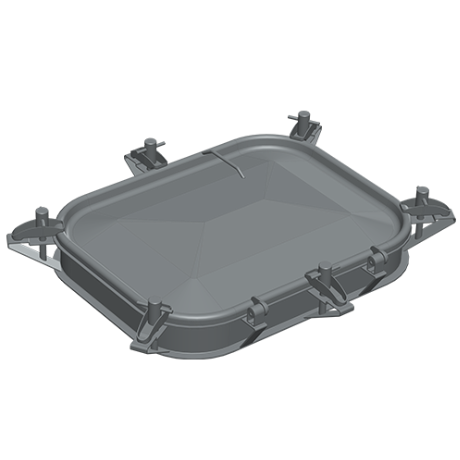

Rectangular manway

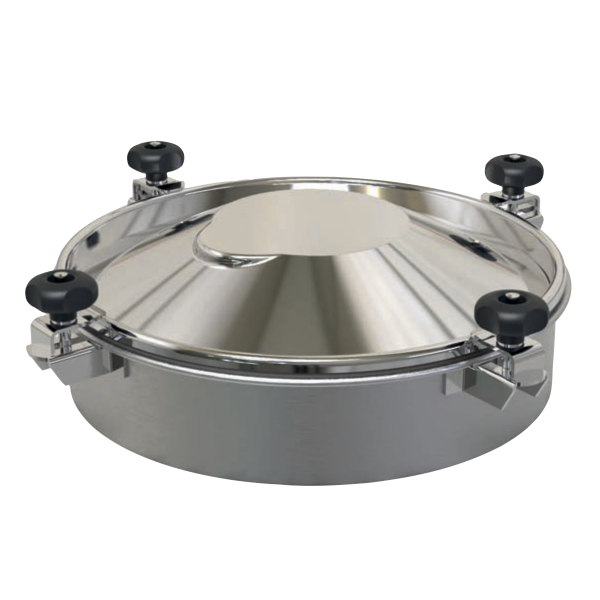

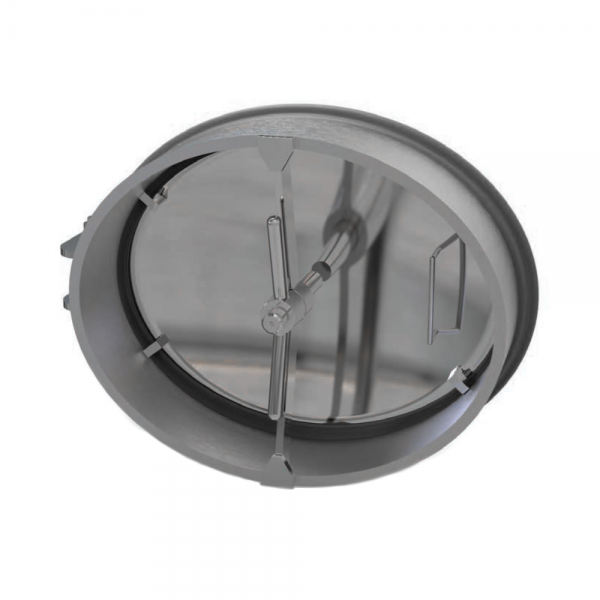

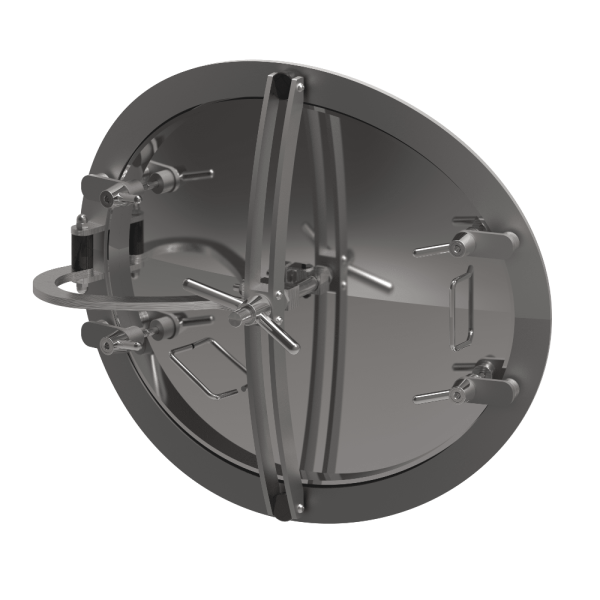

Round manway

Round manway

Round manway

Round manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Oval manway

Oval manway

Oval manway

Oval manway

Oval manway

Round manway

Round manway

Round manway

Round manway

Round manway

Rectangular manway

Rectangular manway

Round manway

Round manway

Round manway

Rectangular manway

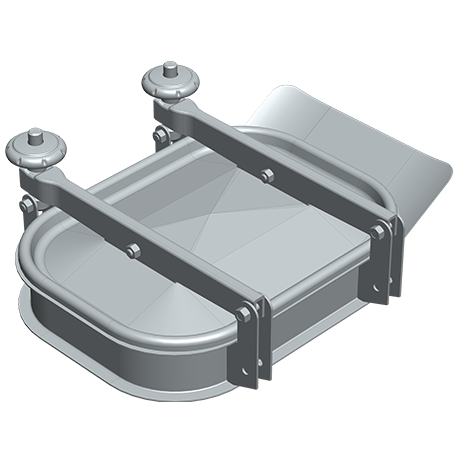

Special-purpose manway

Rectangular manway

Rectangular manway

Manway gasket

Oval manway