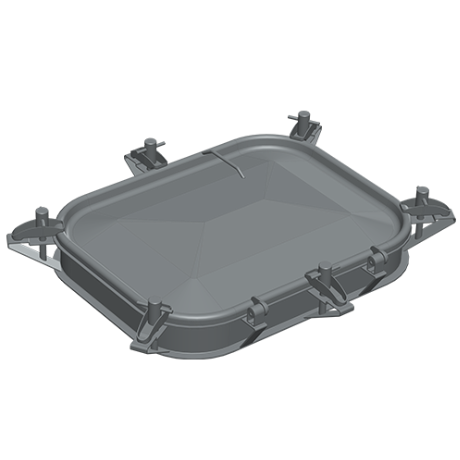

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway