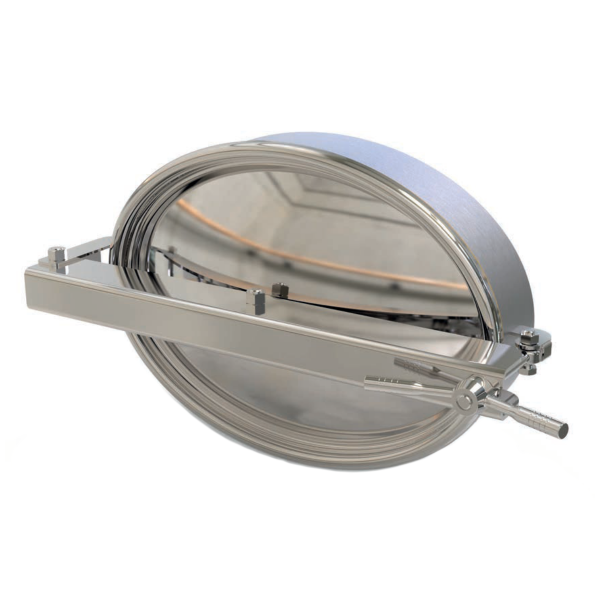

A characteristic feature of oval manways is the fact that some of them can be manufactured only for special order – these are oval manways bent to the diameter of the tank.

In case of bent manways, the selected model is manufactured according to the declared diameter/radius parameter of the tank, in which the manway is to be installed by default. An extremely practical aspect of this type of solution is the possibility to obtain a highly aesthetic design, in which the frame of the inspection opening (manway) does not protrude beyond the outline of the tank shell.

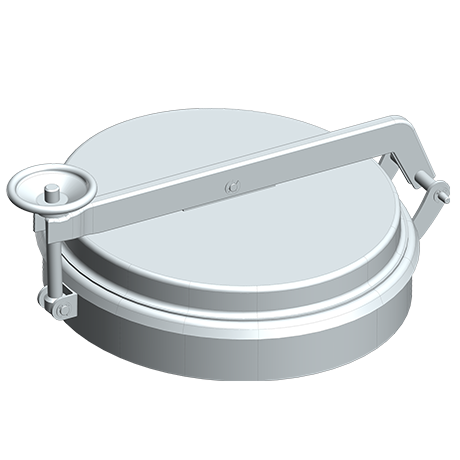

For oval manways, a special cover with a door is provided as an accessory that allows thermal insulation of the main manway opening. This is particularly desirable when using oval manways in thermally insulated tanks.