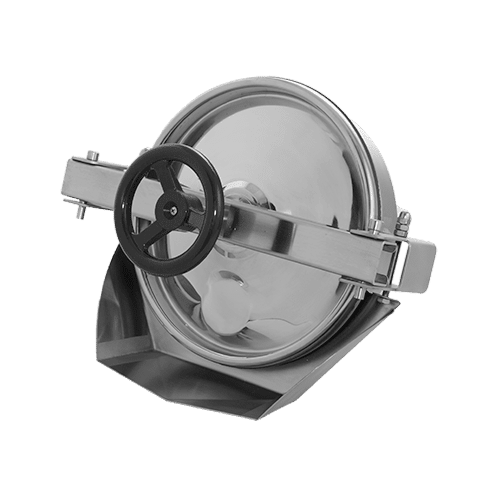

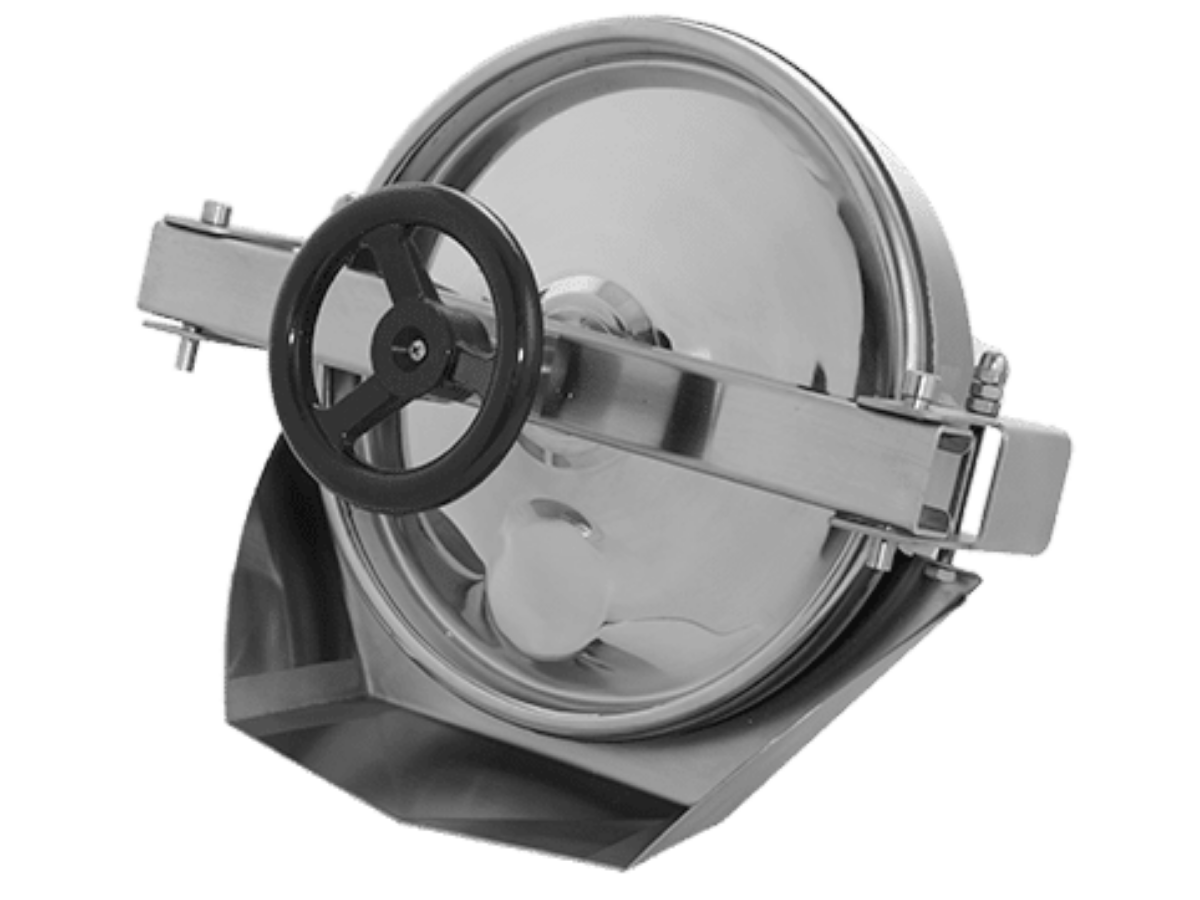

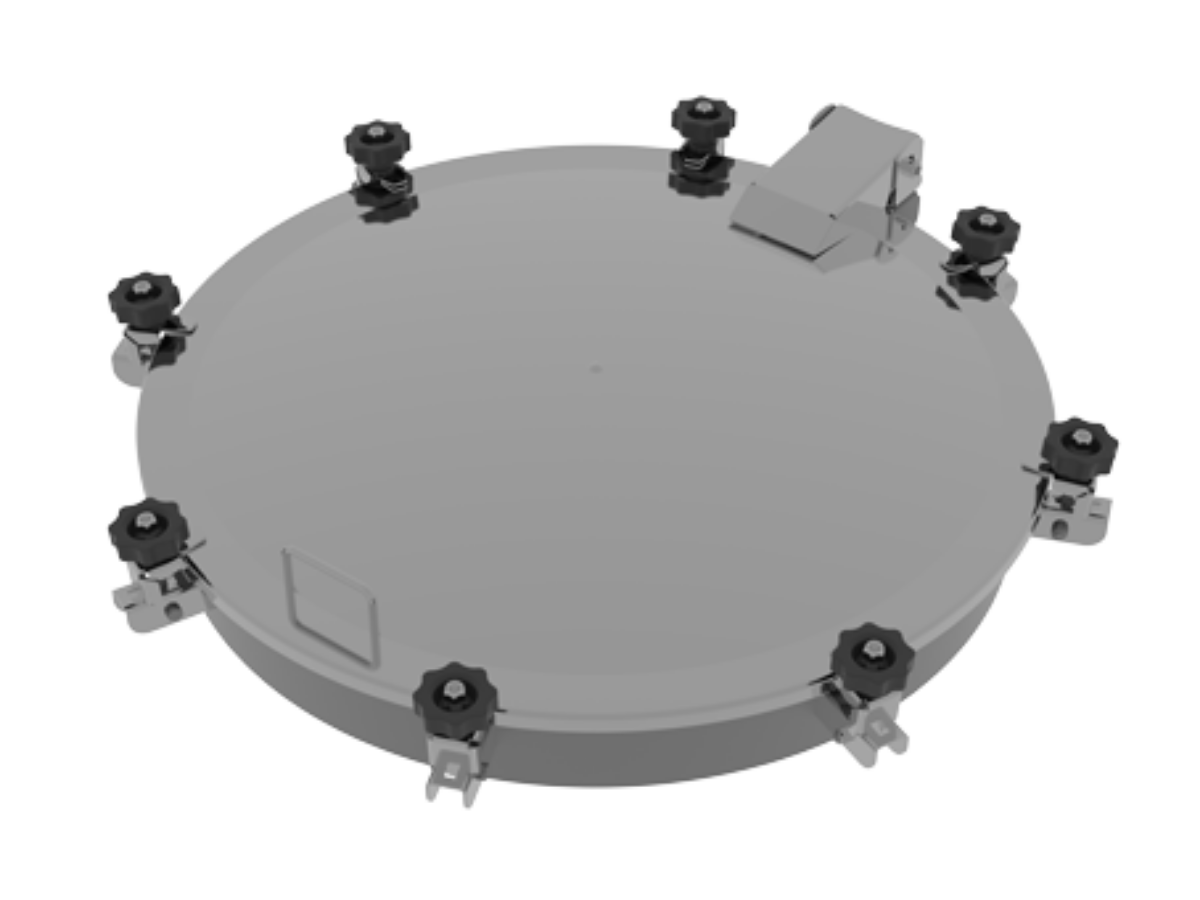

Each round manway has a mounting element in the form of a frame. It is a part of a manway directly mounted in the surface of a tank or industrial equipment, in which an appropriately sized hole has been prepared in advance. Most often the mounting process is carried out by welding.

The range of the frame height parameter (often designated as "H") varies depending on the manway model. Most round manways include a height range of 60-150 mm in their specification. For standard models, the most common value is 60 mm. The designs of some manways provide for heights up to 250 mm, 500 mm or even 1000 mm. The frame height parameter is particularly important for thermally insulated tanks, where the thickness of the thermal insulation must be taken into account when fitting the equipment.

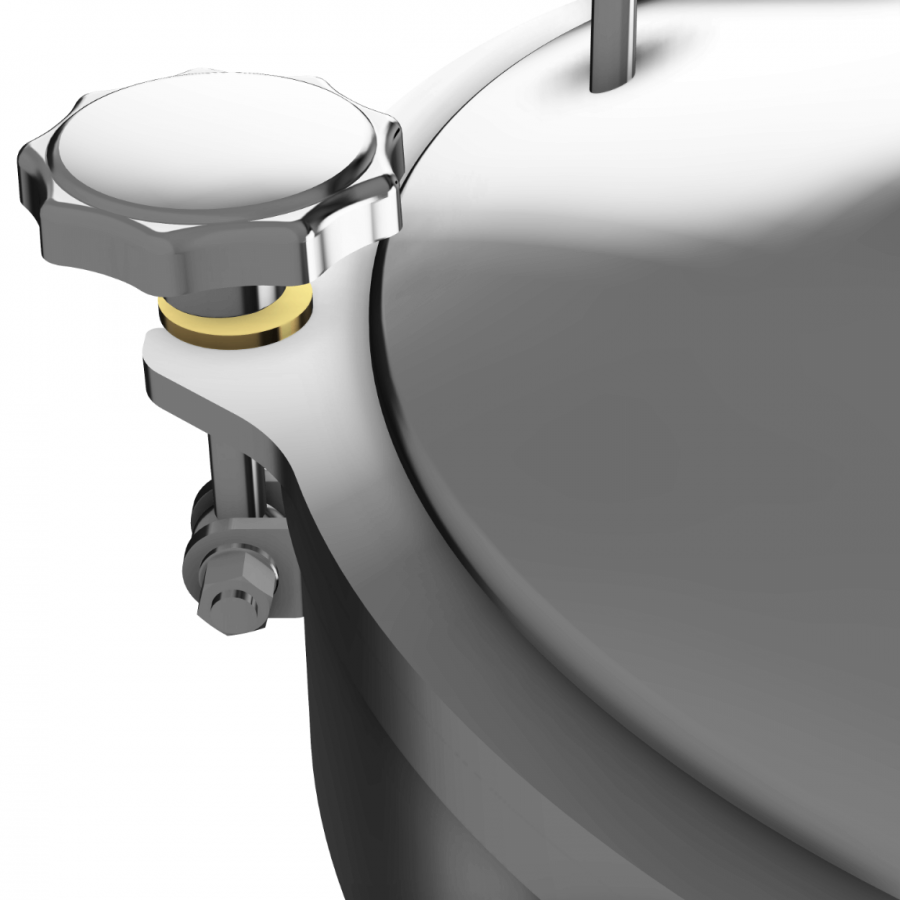

As important a parameter as the height of the frame is the thickness of its wall (often designated "SP"). The thickness of a manway frame can vary significantly depending on its intended use. For standard round stainless steel lids, this value will usually be around 2 mm. For pressure manways, the manway wall thickness is 8 mm, 10 mm or greater.