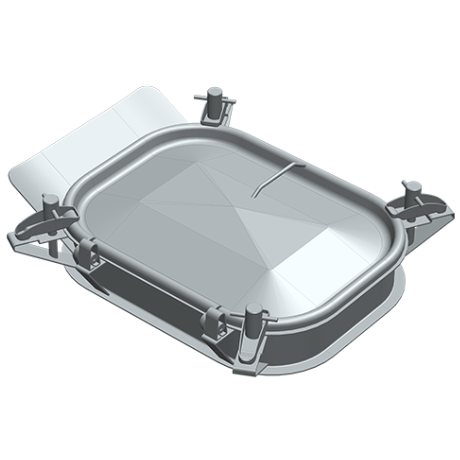

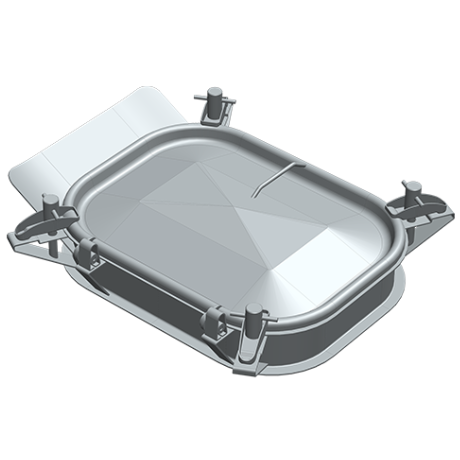

Special-purpose manway

Special-purpose manway

Special-purpose manway

Special-purpose manway

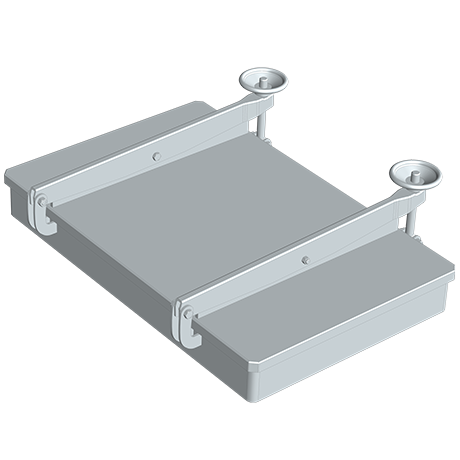

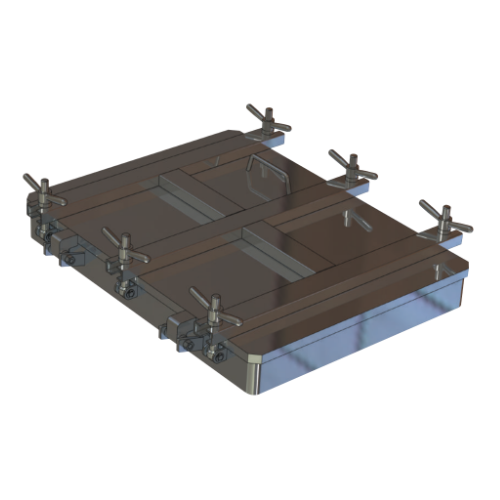

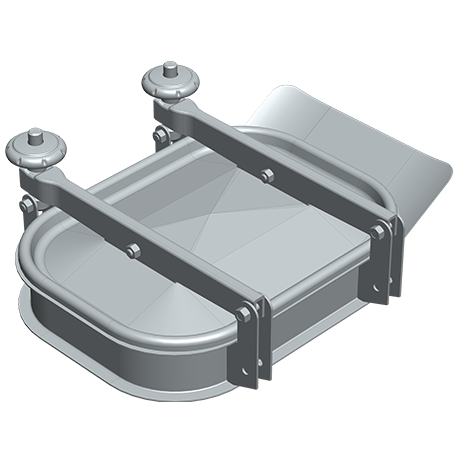

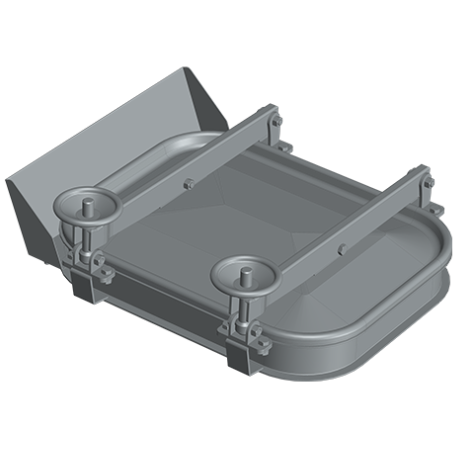

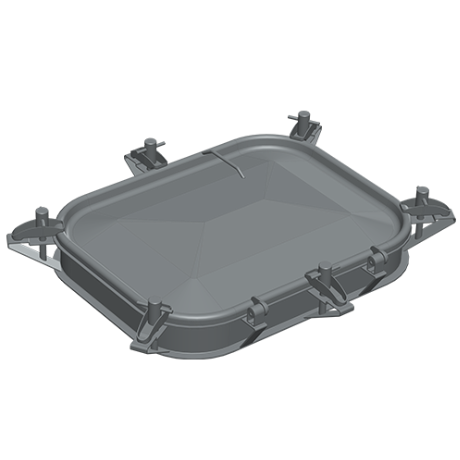

Rectangular manway

Rectangular manway

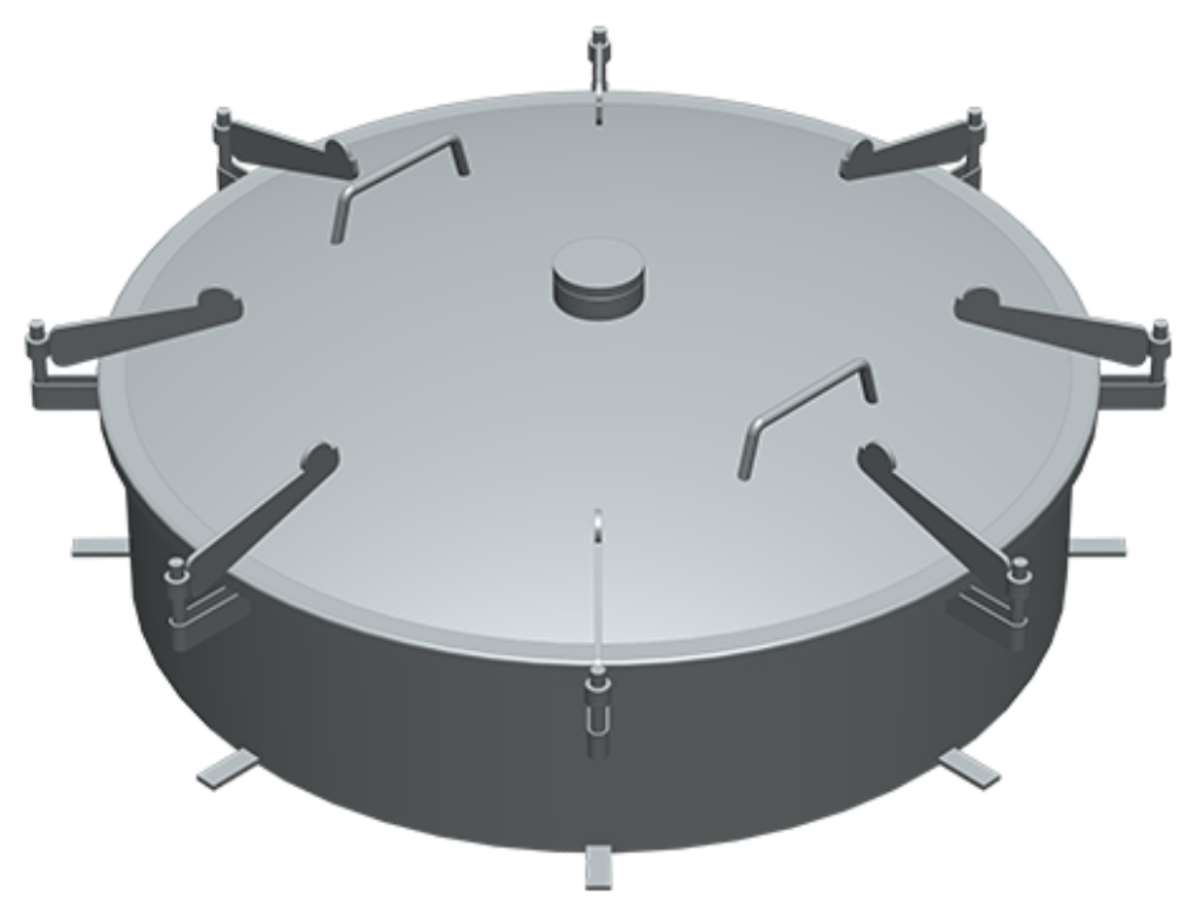

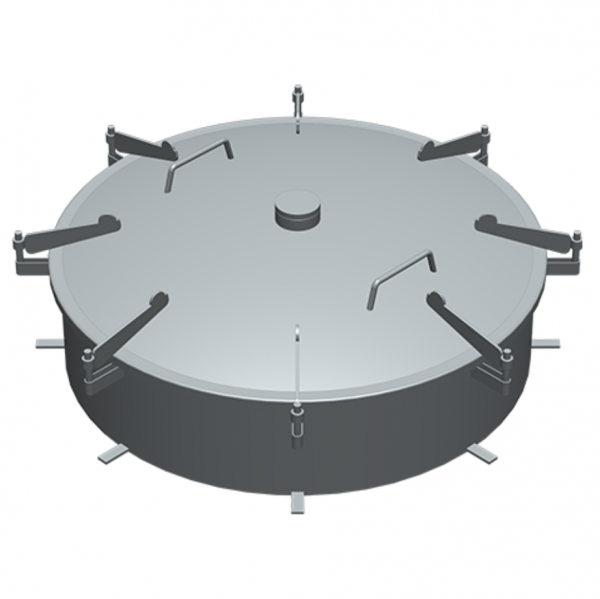

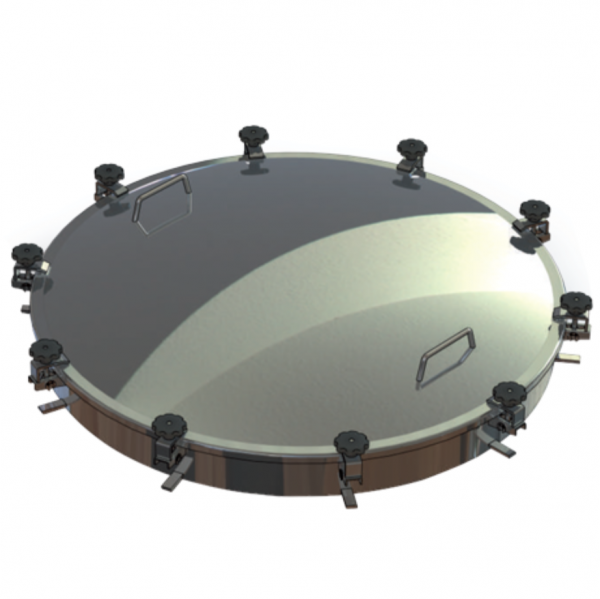

Round manway

Round manway

Round manway

Rectangular manway

Round manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Rectangular manway

Round manway