Round manway

E/1M (DN223-DN1540)

Round manway series E/1M

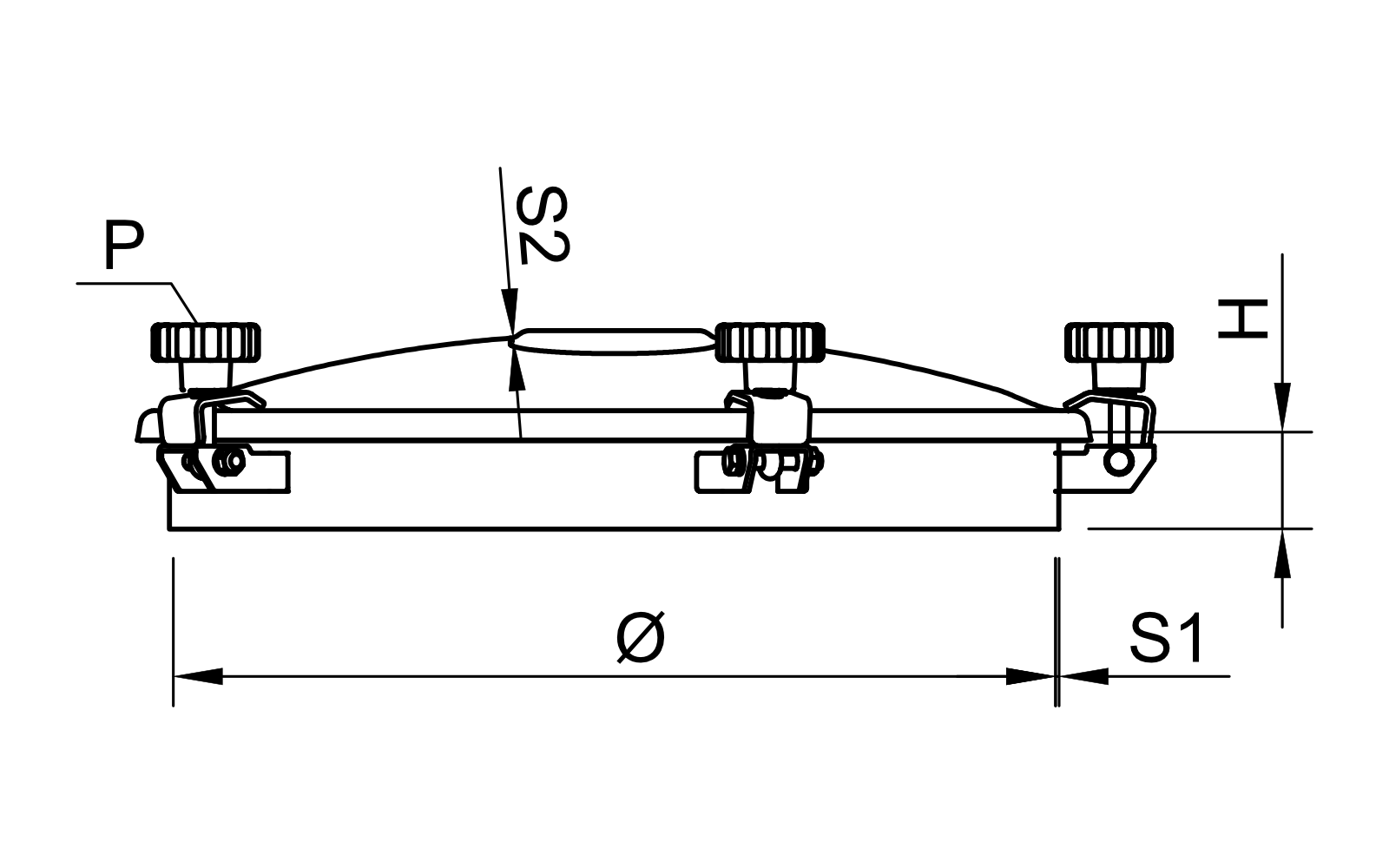

Round stainless steel manways of E/1M series are designed for installation in the roof of a stainless steel tank. They also work well as inspection lids for smaller tanks. A feature of E/1M series manways is their completely removable cover, which is pressed on using handwheels (from 3 to 5 pieces - depending on the diameter of the manhole).

An additional advantage of round manways of the E/1M series is their convex cover, which does not retain water on its surface.

The manway is manufactured in two versions:

- E/1M (with a gasket mounted on the frame),

- E/C1M (with a gasket mounted in the cover).

Large-diameter options up to DN1540 are also available.

The large range of available mounting frame heights (see table) makes manways of this family easy to build into stainless steel insulated tanks. E/1M round manways are installed in stainless steel tanks designed for storing various types of products, as well as in many other devices.

The use of stainless steel round manways series E/1M

The main areas of application for these types of manways are: food, dairy, beverage and liquor industries. They are also used with good results:

- in vegetable and fruit processing,

- in the cosmetics industry,

- in the biotechnology and chemical industries.

E/1M series manways are an excellent piece of equipment for non-pressurized devices requiring an inspection lid in their design. In general, manways of this type can be installed wherever the parameters of the materials used in its construction allow the application.

Standard versions (gasket on the frame)

| Model | Ø [mm] | H [mm] | S1 [mm] | S2 [mm] | Pokrętła | MAX [bar] |

|---|---|---|---|---|---|---|

| E22/1M | 223 | 60 90 150 200 250 300 400 500 |

2 |

1.5 |

3 | 0.1 |

| E30/1M | 302 | 2 | 1.5 | 3 | ||

| E40/1M | 402 | 2 | 2 | 4 | ||

| E45/1M | 455 | 2 | 2 | 4 | ||

| E50/1M | 502 | 2 | 2 | 5 | ||

| E60/1M | 602 | 2 | 2 | 5 |

Standard versions (gasket in the cover)

| Model | Ø [mm] | H [mm] | S1 [mm] | S2 [mm] | Pokrętła | MAX [bar] |

|---|---|---|---|---|---|---|

| E30/C1M | 302 | 60 90 150 |

2 | 1.5 | 3 | 0.1 |

| E40/C1M | 402 | 2 | 2 | 4 | ||

| E45/C1M | 455 | 2 | 2 | 4 | ||

| E50/C1M | 502 | 2 | 2 | 5 | ||

| E60/C1M | 602 | 2 | 2 | 5 |

Large diameter versions

| Model | Ø [mm] | H [mm] | S1 [mm] | S2 [mm] | Pokrętła | MAX [bar] |

|---|---|---|---|---|---|---|

| E80/1M | 792 |

100 150 200 250 300 350 400 |

3 | 2 | 8 | 0.05 |

| E90/1M* | 890 |

100 200 300 400 |

3 | 2 | 10 | |

| E100/1M* | 1020 | 3 | 2 | 10 | ||

| E120/1M | 1210 | 3 | 3 | 10 | ||

| E140/1M | 1370 | 3 | 3 | 12 | ||

| E160/1M | 1540 |

100 200 |

3 | 2 | 12 |

*Gasket in the cover.

Technical parameters

| Product series | Series E |

|---|---|

| Shape | Round manways |

| Type | Non-pressure manway |

| Frame height (in mm) | 60-500 mm |

| Frame wall thickness (in mm) | 2.0 mm |

| Opening type | Outward |

| Industry | Brewing, Chemical, Dairy, Food production, Winemaking |

| Size | DN300 - DN500 |

| Mounting method | in the tank roof (top manways) |

| Pressure | below 0.5 bar |

| Vacuum pressure | not applicable |

| PED certificate | no |

| Steel grade | AISI 304/304L, AISI 316/316L |

| Gasket material | EPDM, NBR, Silicone, Viton |

| Handwheel material | Plastic, INOX |